ESG is a critical metric for gauging sustainability in corporate management, driving transformative shifts from strategic planning to fundamental business model changes. In recent years, regulatory frameworks across nations and industries have evolved significantly, prompting Korean businesses to conduct ESG assessments and ultimately to establish long-term ESG implementation strategies to secure their competitiveness.

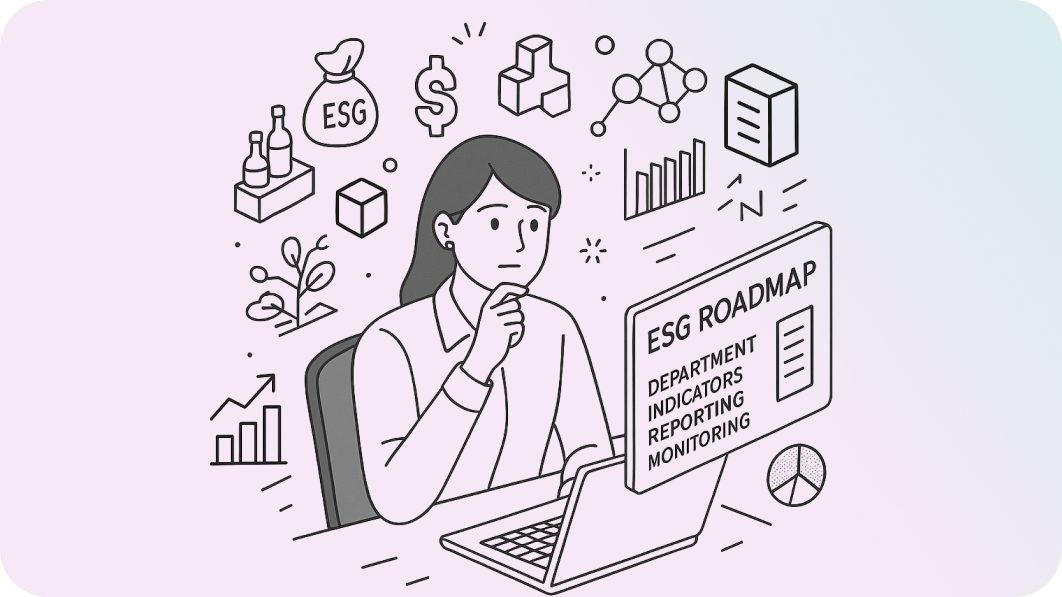

To navigate this rapidly evolving ESG landscape, businesses must adopt a strategic approach that includes system-based ESG data management, enhanced board oversight, innovation in products and services that incorporate ESG factors, and company-wide ESG engagement. LG CNS provides a one-stop service, from developing roadmaps and deploying ESG implementation frameworks to introducing and providing operational support for IT solutions for monitoring, ensuring an impactful and practical approach to ESG adoption and integration.

ESG Strategy and Management Framework

For tailored ESG management, we analyze diagnostic ESG items based on global initiative requirements and benchmarking against industry leaders and competitors to identify key improvement areas.

To develop a company-wide ESG strategy framework, we set ESG objectives aligned with your corporate vision and review the entire schedule and roles and responsibilities (R&R), such as for an ESG Committee and evaluation and disclosure responses, to ensure integration with existing operations. In addition, we establish a department-level monitoring system for ESG indicators and tasks, allowing for continuous mid- to long-term review of the ESG roadmap and laying the foundation to become a leader in ESG.

ESG Disclosure and Evaluation Response

We facilitate ESG performance disclosure that complies with various standards, including GRI, ISSB, and ESRS, and by deploying customized indicator management systems for each client and industry, we provide a solid foundation to meet global market demands, from the EU to the US. Specifically, we analyze mandatory and voluntary disclosure requirements along with internal and external evaluation criteria, and define data elements, including definitions, formats, responsible departments, sources, and aggregation cycles, to deploy a systematic indicator management system that integrates previously Excel-managed data into a single platform.

Climate Change Response Strategy

In response to the increasingly sophisticated stakeholder demands regarding carbon neutrality, we offer comprehensive support from developing carbon neutrality strategies and preparing TCFD reports to measuring product carbon footprints. Specifically, we support the entire process, from current status assessments and BAU(Business As Usual) calculations to action planning and roadmap development, for the development and review of carbon neutrality strategies, while evaluating transition and physical risks in financial terms to determine their fiscal impact for TCFD disclosures. Moreover, by defining organizational boundaries and monitoring greenhouse gas reduction initiatives, we establish an advanced emissions management framework and develop a product carbon footprint calculation system to meet diverse requirements.

Supply Chain ESG Risk Management

To comply with EU supply chain due diligence regulations and manage Scope 3 greenhouse gas emissions, we establish ESG and human rights risk assessment and management frameworks—both general and industry-specific—and develop roadmaps based on the scale, industry distribution, and regional characteristics of all suppliers. Our service covers the entire deployment process, from defining evaluation criteria and operational policies to facilitating supplier self-assessment questionnaires (SAQ), setting improvement targets, and monitoring corrective actions, while enhancing the overall sustainability of the business value chain by introducing IT systems for efficient ESG risk management among suppliers.

LG CNS delivers a comprehensive platform service for data-driven ESG management, covering everything from an ESG portal to performance monitoring and disclosure management. The platform integrates diverse ESG-related data within a single system effectively supporting risk management as well as evaluation and disclosure tasks. This integrated approach enables companies to achieve systematic and effective ESG performance evaluation and disclosure management.

Establishing a Scalable and Flexible ESG DX Management Foundation

- End-to-end integrated measurement and management of data, from KPI tracking to disclosure reporting

- A design with high scalability and flexibility, to accommodate diverse internal and external data connections

Applying LG Group’s Expertise in Consulting, Deployment, and Operation

- A reservoir of insights accumulated and internalized through years of operational excellence within the LG Group

- A verified industry-specific system, optimized for a wide array of sectors

A Platform Capable of Continuous Evolution

- A platform that easily expands its scope, including broader applications and indicator extensions

- Realizing ESG Intelligence through enhanced functionality that supports strategic decision-making and ensures data reliability

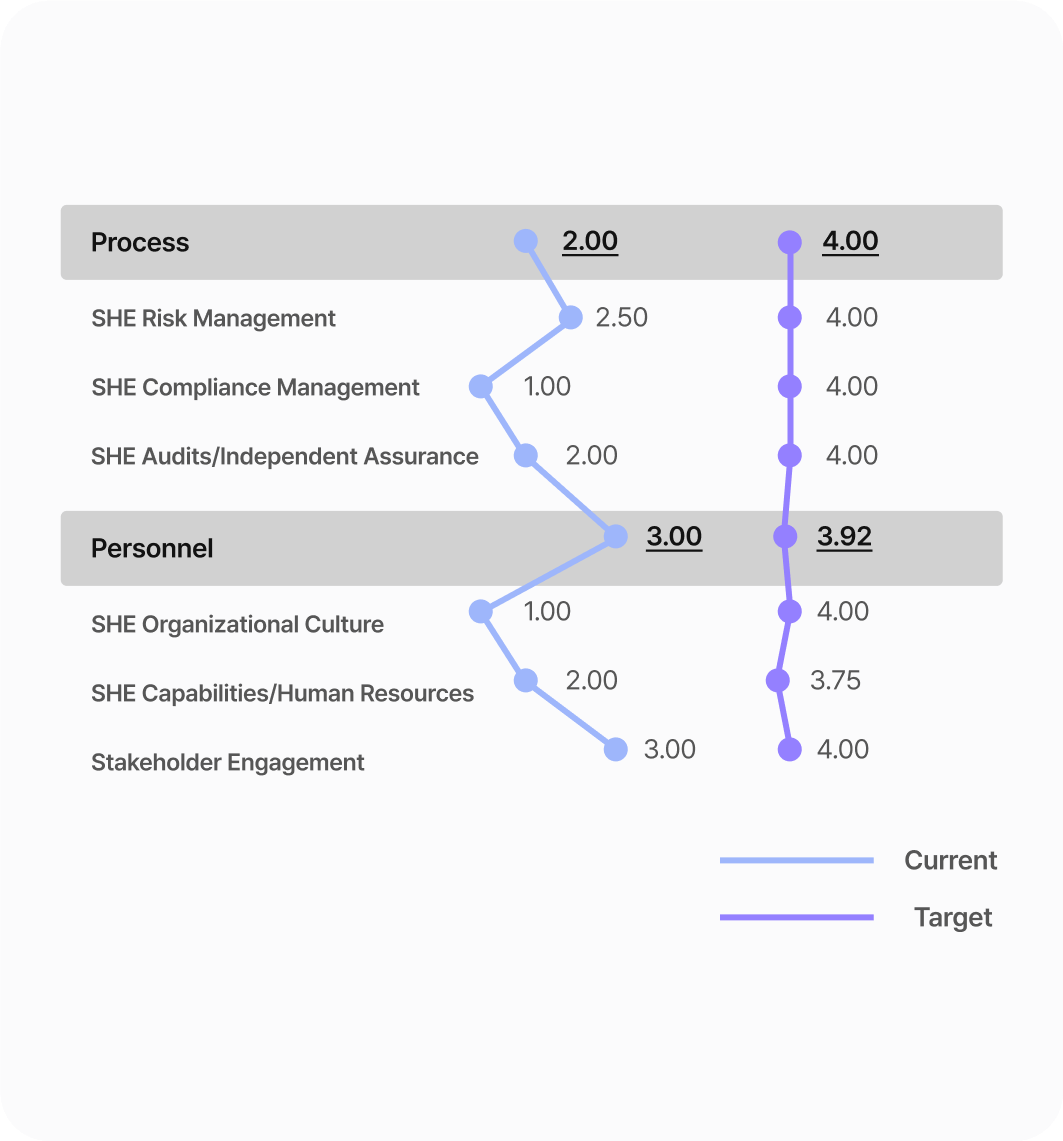

We provide comprehensive diagnostics of your organization's safety environment maturity across governance, technology, process, and people. By analyzing the current condition and comparing it against target benchmarks, we diagnose the level of digitalization in your safety management and present a prioritized, phased roadmap for future improvements.

LG CNS delivers tailored digital safety consulting by benchmarking your organization’s processes against the LG CNS Safety Environment Standard Process*, helping you define a digitalization strategy and direction, set implementation priorities, and identify improvement tasks and roadmaps aligned with your specific needs.

* LG CNS Safety Environment Standard Process

* A set of standardized processes developed with reference to safety and environment practices from LG Group and external domains, consisting of 5 Process Chains, 20 Process Groups, 64 Processes, and 189 Activities.

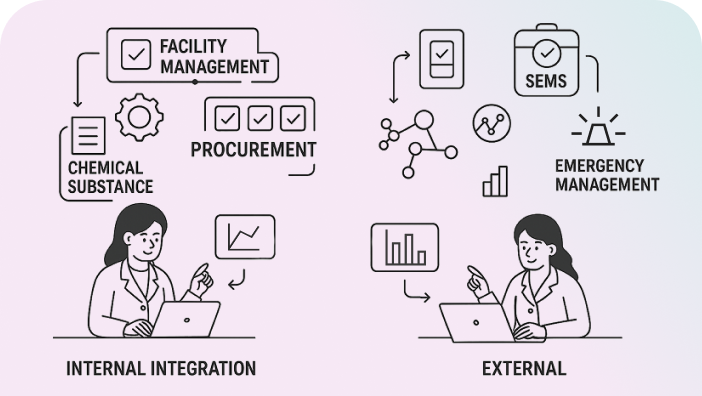

LG CNS delivers end-to-end services that integrate DX technologies to enable informatization, automation, and intelligent control to encompass safety, health, environment, chemical substance management, and regulatory compliance.

Safety and environmental management can be integrated at headquarters, production sites, and partner companies, along with data generation, collection, and integration with relevant systems. All of these capabilities are provided through the LG CNS Safety Environment Portal solution.

By applying advanced DX technologies, LG CNS helps reduce costs, drive innovation, and improve asset efficiency. Intelligent operations in safety, energy, and facilities, powered by AI and optimization algorithms, combined with cloud-based data collection using IoT sensors, real-time monitoring, and predictive analytics, enable the enhancement of proactive risk detection and preventive actions. We also support VR/AR-based training and automated compliance management to enhance efficiency and reduce operational costs.

The LG CNS SHE Portal is a leading safety and environment platform that was purpose-built for the SHE domain, designed based on verified success cases across the LG Group. The solution supports compliance with the Serious Accidents Punishment Act, enables proactive risk management to prevent safety and health incidents, and strengthens oversight in the safety and health practices for partner companies.

Built on LG Group’s proven know-how, the solution aims to foster a culture of safety that goes beyond operations with zero-incidents and takes root as a lasting part of the industrial workplace, ensuring a safer tomorrow.

-

Traditional safety environments rely heavily on manual data collection, paper-based reporting and communications, and periodic inspections with reactive responses. In contrast, digital safety environments use IoT sensors and cloud-based systems to collect and analyze data in real time, enabling instant communication and automated reporting through digital platforms. Digital safety environments enhance early risk detection and prevention through real-time monitoring and predictive analytics, while VR/AR-based training and automated compliance management boost operational efficiency and reduce costs.

-

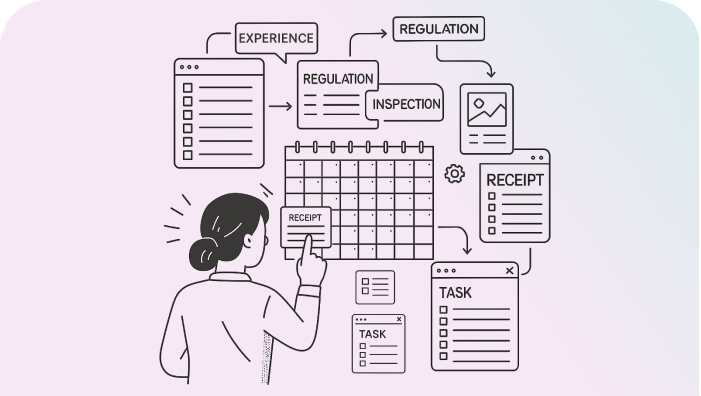

A structured approach is essential when considering the introduction of a digital safety environment, and LG CNS recommends a three-phase methodology. First, "Digital Safety Environment Maturity Diagnostics" are conducted to evaluate the current level of safety management within the organization and to identify which areas require digital transformation. This helps clearly define areas for improvement and establish priorities. Next, LG CNS develops a tailored digital safety environment implementation strategy through "consulting," which includes reviewing standard processes, setting goals, selecting technologies, and planning the budget. Finally, LG CNS builds a "digital safety environment system" by integrating DX technologies such as AI, optimization algorithms, IoT sensors, cloud-based systems, and data analytics tools , enabling real time decision-making based on data and supporting continuous operations and maintenance.

-

LG CNS offers not only implementation-based solutions, but also subscription-based services. The subscription model lowers the initial cost burden and allows organizations to quickly adopt the necessary features based on their specific needs and operational context. It also includes ongoing updates and maintenance, ensuring access to the latest technologies.

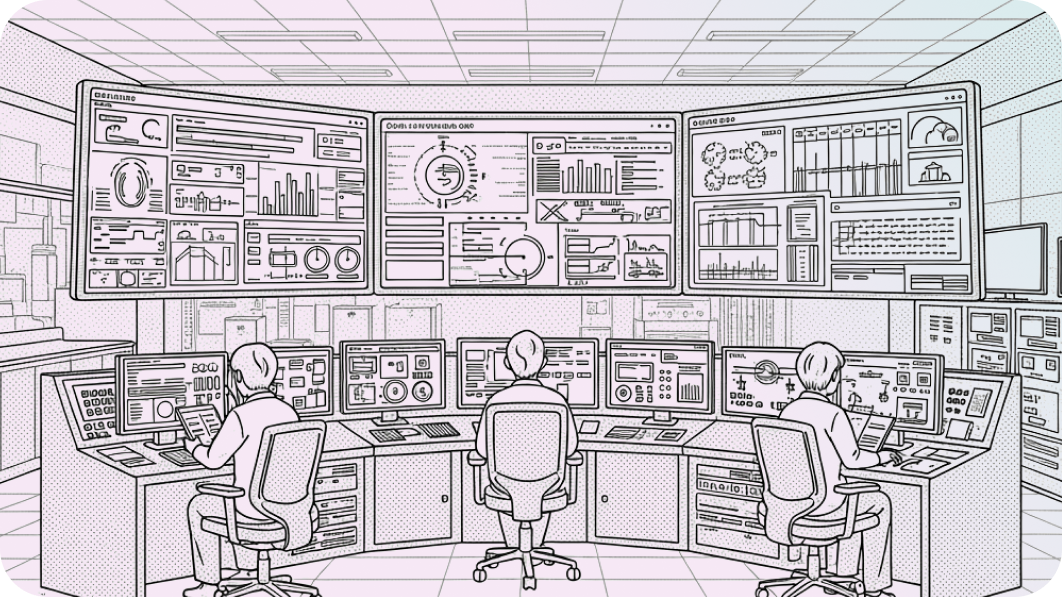

A physical integrated control center allows for immediate recognition and response by collecting and monitoring key data on safety, environment, energy, processes, and equipment while detecting unusual situations in real time.

Data collected from heterogeneous systems is unified via the control platform, allowing for real-time, end-to-end monitoring. When a risk is identified, the system automatically verifies field conditions and facilitates fast, informed decision-making to minimize damage.

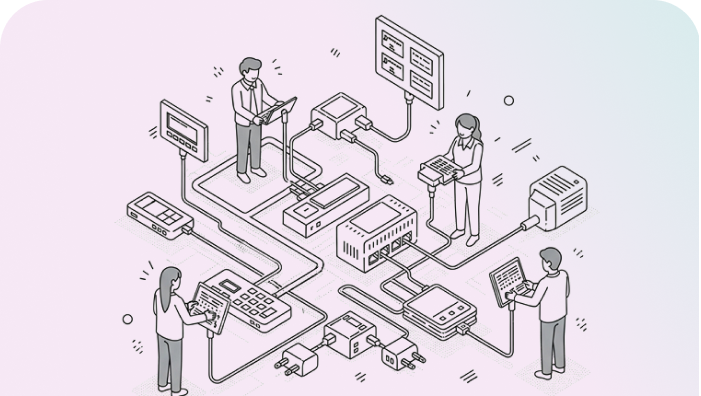

Integrating systems with various devices and protocols can be technically complex. Different protocols involve different data transmission formats, messaging schemes, and connection settings, making standardization and integration challenging. The "Smart Connect" adapter enables easy connection and monitoring without additional development simply by adding the specific adapter needed for each device.

Digital technologies centralize fragmented data to enhance operational efficiency and support real-time insights to speed up decision-making. The system provides realistic visualizations of monitoring data through an intuitive 3D dashboard and delivers immediate guided actions through electronic action manuals when alarms are triggered or certain events transpire.

(Safety & Environment Platform)

"αOP" is an integrated operations platform optimized to support the design and operation of centralized control systems, providing a comprehensive set of capabilities, such as monitoring, control, alarm processing, event history management, trends and statistical analytics, user notifications, and operator response processing based on real-time data collected from a wide range of equipment (facility/utility), devices, gateways, and sensors. Using the platform’s built-in Smart Builder, control dashboards can be flexibly designed across various formats, including dashboard-style layouts, equipment network diagrams, tables, GIS-based maps, and architectural drawings.

The platform also provides comprehensive operational processing support that includes everything from event detection and handling to action guidance, facility status checks, and event history management. In the event of a critical incident, Standard Operating Procedures (SOPs) essential for a response can be quickly and intuitively generated and applied through simple event association settings.

To support efficient task processing by user type, LG CNS provides optimized viewers for each work role, including Smart Viewer Pro for professional control personnel, a web viewer for general users, and a mobile viewer for on-site patrol users. As integrated control requires uninterrupted operation 24 hours a day, 365 days a year, service continuity and stability are ensured through Active-Standby and Active-Active configurations. Come and build a safe manufacturing environment with Factova SEP, which provides integrated management of risk data and systematic response through monitoring.

-

The most important factors are improving operational efficiency and establishing a real-time response system. An integrated monitoring setup should provide a consolidated view of key safety and environmental conditions across the entire site. The system must detect anomalies in real time using video feeds, monitoring sensors, disaster detection systems and administrator inputs, and automatically provide appropriate dashboards and response information based on the level of risk: normal, caution, high alert or critical. It is also essential to unify dispersed monitoring systems into a single integrated architecture that enables the immediate recognition of and response to on-site incidents.

-

Physically separated sites facilities typically require dedicated control centers at each site. However, the integrated control platform is cloud-based, allowing for unified monitoring across all sites. Even when control centers are physically independent, real-time monitoring and control is possible through standardized network configurations, and an integrated database structure enables comprehensive data collection and analytics across all sites. This allows a centralized integrated control system to be built even in physically separated environments.

_RGB_crop.jpg)