The adoption of digital technologies in supply chain management is accelerating as companies seek to enhance operational efficiency by predicting market changes and responding proactively. The increasing complexity of supply chain operations—driven by expanding product lines to meet diverse consumer demands and the globalization of business operations—has been further compounded by external disruptions such as natural disasters, wars, terrorism, labor strikes, and workforce shortages.

To maintain supply chain stability, industry leaders are utilizing digital technologies such as AI and optimization to: ① diversify and localize supply chains to mitigate risks and enhance responsiveness, ② build agile supply chains that can adapt to rapid changes, ③ leverage client data analytics to provide personalized services, and ④ maximize supply chain efficiency through enhanced collaboration with stakeholders.

LG CNS provides Supply Chain Management (SCM) Services across strategy, planning, and execution. We have extensive experience in SCM consulting and system implementation, applying digital technologies across industries such as manufacturing, distribution, and logistics.

SCM Diagnostics & Process Innovation (PI) Consulting

LG CNS diagnoses SCM operations strategies, processes, systems, Key Performance Indicators (KPIs), and organizational structures to assess supply chain performance and establish a master plan and long-term roadmap. We design SCM frameworks tailored to specific industries, identify process enhancement, and provide change management consulting to ensure successful execution.

SCM Optimization

We apply optimization and heuristic methodologies to address complex supply chain challenges, such as: determining optimal inventory levels to manage demand fluctuations, identifying cost-effective logistics hubs to minimize distribution expenses, optimizing procurement strategies to reduce sourcing costs and defining optimal workforce and equipment allocation to meet production targets efficiently.

SCMable is a SaaS-based service designed to solve key supply chain challenges without requiring system establishment. It provides solutions for inventory optimization, procurement optimization, workforce allocation optimization, capacity planning, cutting stock optimization, and logistics hub optimization.

SCMable’s flexible, pay-as-you-go model minimizes upfront investment and allows clients to customize the solution to their needs.

Demand Management System Implementation

Defining the necessary system functions for demand management, LG CNS provides customized implementation strategies tailored to each client's operational needs. Our service includes system implementation, launch, stabilization, and change management. By adopting AI technology, our solutions support Demand Planners (DPs) in enhancing operational efficiency across various demand management roles.

Collaborative Planning Forecasting & Replenishment (CPFR) – establishing sell-out forecasting and inventory-level collaboration between suppliers and clients.

Demand Fulfillment (DF) System – allocating supply to orders and providing accurate delivery commitments.

Enterprise-wide Demand Management (DM) System – integrating financial planning, profitability analysis, and statistical demand forecasting.

AI-powered demand forecasting – applying machine learning to enhance demand planning accuracy.

Supply & Production Management System Implementation

LG CNS defines the essential system functionalities required for supply and production management, providing an end-to-end service that covers system implementation, launch, stabilization, and change management.

Based on the client’s business characteristics, investment scale, and system performance, we offer flexible options, including in-house system development or solution adoption. Our solutions are designed to enhance SCM Planners' operational efficiency.

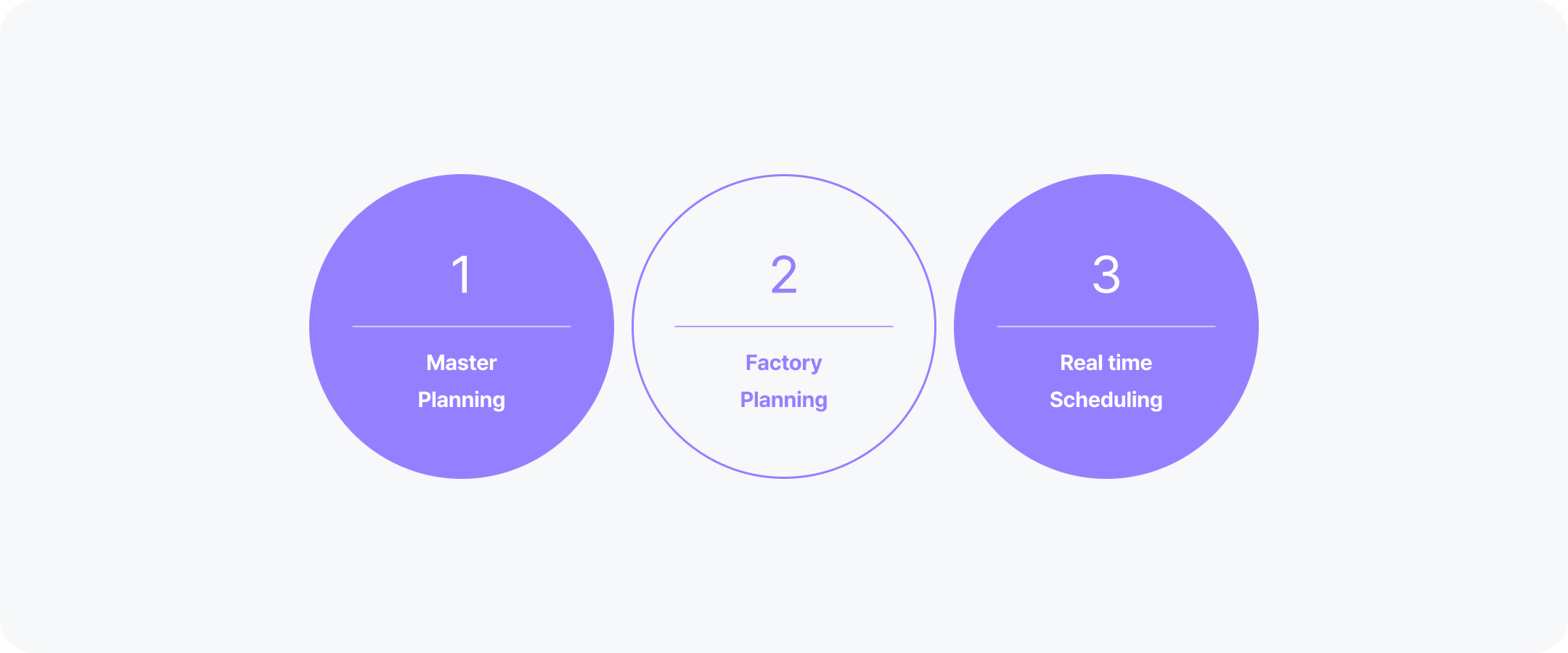

Master Planning System develops an optimized shipping plan by analyzing demand forecasts while considering capacity constraints, material availability, and supply limitations.

Factory Planning System establishes production and equipment-specific work plans to maximize productivity within resource constraints, ensuring efficient production execution based on supply planning.

Real-Time Scheduling (RTS) System enables real-time sequencing of production lines and equipment allocation within the predefined production plan.

LG CNS develops and deploys logistics execution systems, enabling manufacturers, freight forwarders, and logistics operators to enhance supply chain efficiency through integrated warehouse, transportation, order, and forwarding management solutions.

- Warehouse Management System implements rule-based automation and data analytics for efficient warehouse operations.

- Transportation Management System supports transport planning, shipment tracking, freight cost settlement, and performance analysis.

- Forwarding System enables precise international freight management and seamless cost reconciliation for freight forwarding companies.

- Export-Import Management System manages container bookings, shipment tracking, customs clearance, and export/import documentation.

LG CNS designs and builds procurement and supplier management systems, covering development procurement, strategic sourcing, and material procurement processes.

- System to facilitate collaboration between R&D and procurement teams by sharing market and technology insights, ensuring compliance with development schedules, selecting optimal components, and achieving target material costs.

- Supplier Relationship Management (SRM) system to optimize supplier interactions and engagement.

- System for precise purchasing cost analysis, supporting cost innovation (CI) and in-depth cost evaluation.

- Supplier quotation and contract management system to manage vendor quotations, target pricing, negotiations, final agreements, and contracts.

- Procurement order management system to track material requirements and purchase orders based on production planning.

- Risk management system to monitor supply chain risks, detect issues in real-time, and assess impact.

- Supplier collaboration platform to enable seamless exchange of critical procurement data, including material demand, orders, inventory, and settlement.

WMable is a logistics IT solution designed for warehouse, transportation, and order management. Developed by LG CNS, it integrates industry expertise from electronics, consumer goods, and chemicals, offering both standard processes and additional services tailored to client-specific requirements. It provides cost-competitive advantages over global solutions, with rapid support from domestic experts and stable operational management. WMable also incorporates advanced digital technologies, including optimization and AI, enabling specialized service enhancements.

RMable is a SaaS-based supplier risk management solution. It allows companies to define supplier-specific risk factors and keywords, extracting meaningful insights from news articles, reports, and social media data. Additionally, it utilizes generative AI to generate reports on business status and strategic planning. RMable supports risk assessment not only for multi-tier supply chain partners but also for clients. Offered as a SaaS model, it eliminates upfront investment burdens, allowing businesses to configure and use the service as needed.