The production execution area of smart factories is constantly evolving with technological advancements. This evolution plays a critical role in enhancing the competitiveness of companies by maximizing production efficiency, ensuring quality, and enabling agile responses to client needs at manufacturing sites.

The production execution area is largely composed of three systems: MMD (MES Master Data), MES (Manufacturing Execution System), and WMS (Warehouse Management System).

In today's era of accelerating digital transformation (DX), integrated management of manufacturing reference information is emerging as a core strategy for ensuring data accuracy, consistency, and reliability. Integrated management of reference information enables data consistency across multiple systems and departments, eliminates errors and duplication, and ensures security and compliance. By effectively building a system to integrate and manage data, companies can secure a competitive edge in the market and achieve sustainable growth. The higher the quality of master data integration and management, the more quickly and accurately companies can formulate business strategies.

Connection: Achieving Data Consistency Through Integration

Connecting data between different systems plays an important role in the organic integration and collaboration of systems within a company. We provide a centrally integrated data connection service to ensure data consistency and accuracy and eliminate duplication and errors in various business areas such as production planning, quality control, and material management. This allows companies to secure data consistency between systems and strengthen collaboration between processes.

Flexibility: Data Structures that Respond Quickly to Changes

We provide data management features that allow companies to quickly respond to user requirements and business changes by adding or expanding the scope and capacity of reference data.

Providing users with a standardized interface reduces data duplication and maintains data consistency, thereby increasing data integration and interoperability.

Efficiency: Achieving Scalability While Minimizing Costs

The scalability and cost savings of integrated management of reference data are closely related. A highly scalable reference data integration system enables companies to efficiently handle increased data volumes and complexity without incurring extra costs, and manage new information simply through metadata configuration. It provides effective reference information management capabilities to improve the operational efficiency of the system through automated processes and minimize additional costs when expanding.

MMD is a system that integrates and manages data used by the production execution system. It receives data from upper-level systems, such as models, bills of material (BOM), routing, and equipment information, in real time and automatically links the data to all factory systems. Users can register and update master data for the entire factory in a single system, with changes reflected in real time. New master data can be added and managed through simple metadata configuration without system modifications. New factories or business requirements can be accommodated quickly and cost-effectively by adjusting environment settings.

-

The manufacturing reference information integrated management system is a system that standardizes and manages the reference information of products, processes, materials, and equipment that were previously operated differently by each business unit or product group. This approach helps maintain data consistency and improve operational efficiency.

-

Reference data is the core data required for manufacturing, including production planning, quality control, and supply chain management. Inconsistent reference information can cause errors, duplication, and system disruptions. Systematic integration and management ensure stable, uninterrupted production system operations.

-

The system provides essential functions including the registration, storage and modification of product, process and equipment data required for manufacturing. It also includes business management functions such as access control, version history tracking, deployment management, and approval workflows.

-

When introducing such a system, it is important to consider the organization and standardization of existing data, user training and change management, and data synchronization with related systems. It’s also essential to establish data security frameworks, maintenance and support systems, and to design processes and standards tailored to the industrial environment.

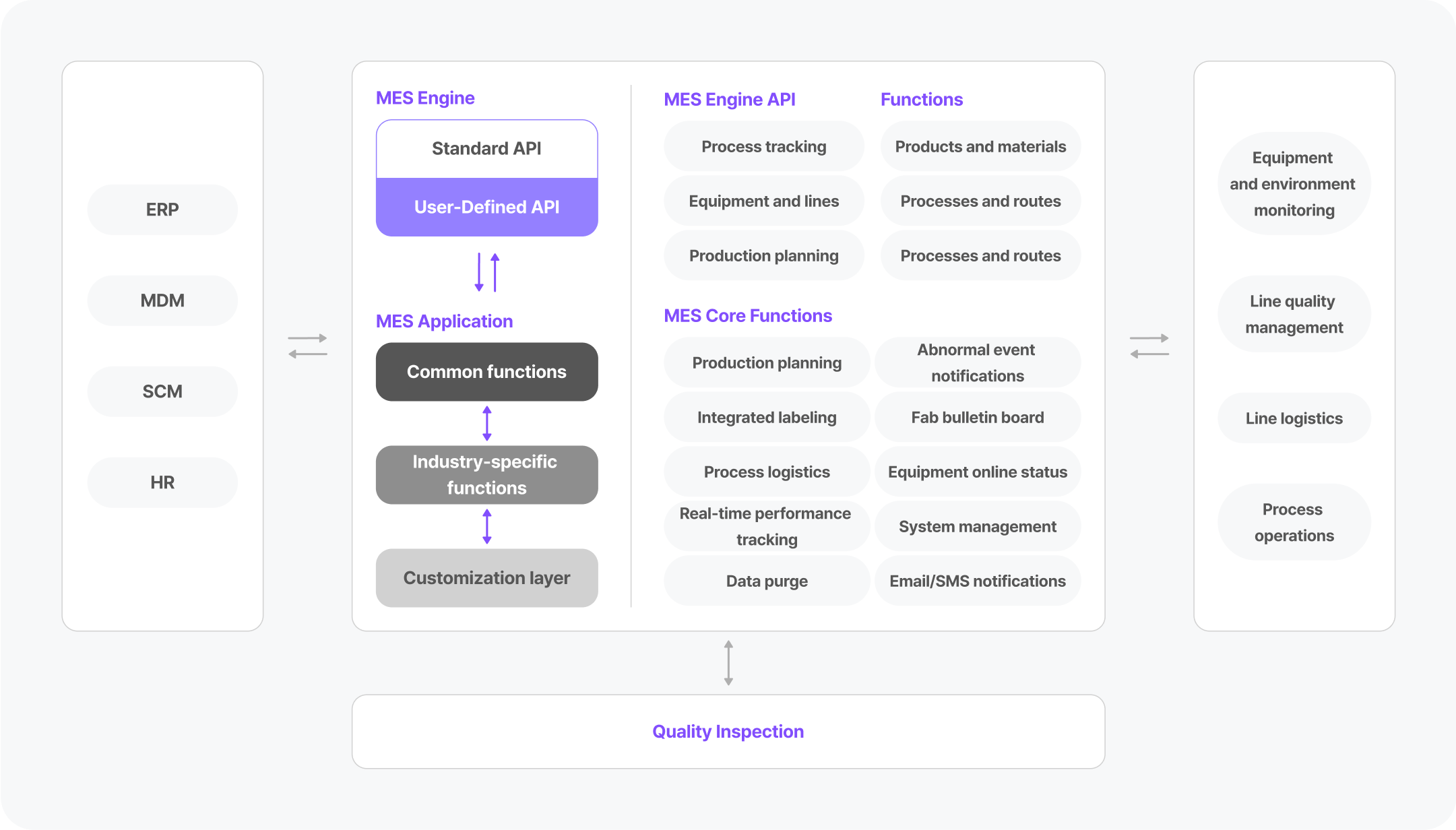

Through the Manufacturing Execution System (MES)

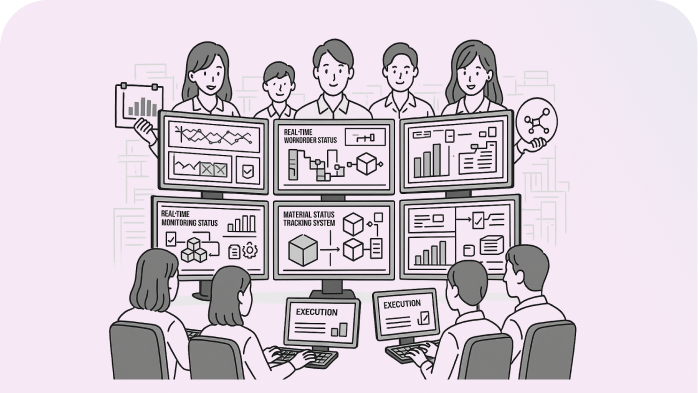

As digital transformation accelerates at manufacturing sites, the importance of systems that automatically control equipment and collect, analyze, and manage data to improve productivity is increasing. The Manufacturing Execution System (MES) is one of the core components of a smart factory. It directs process operations according to production plans, monitors work history and progress in real time, and integrates and manages equipment status and quality data. This enables manufacturing companies to operate production activities in a systematic and automated manner.

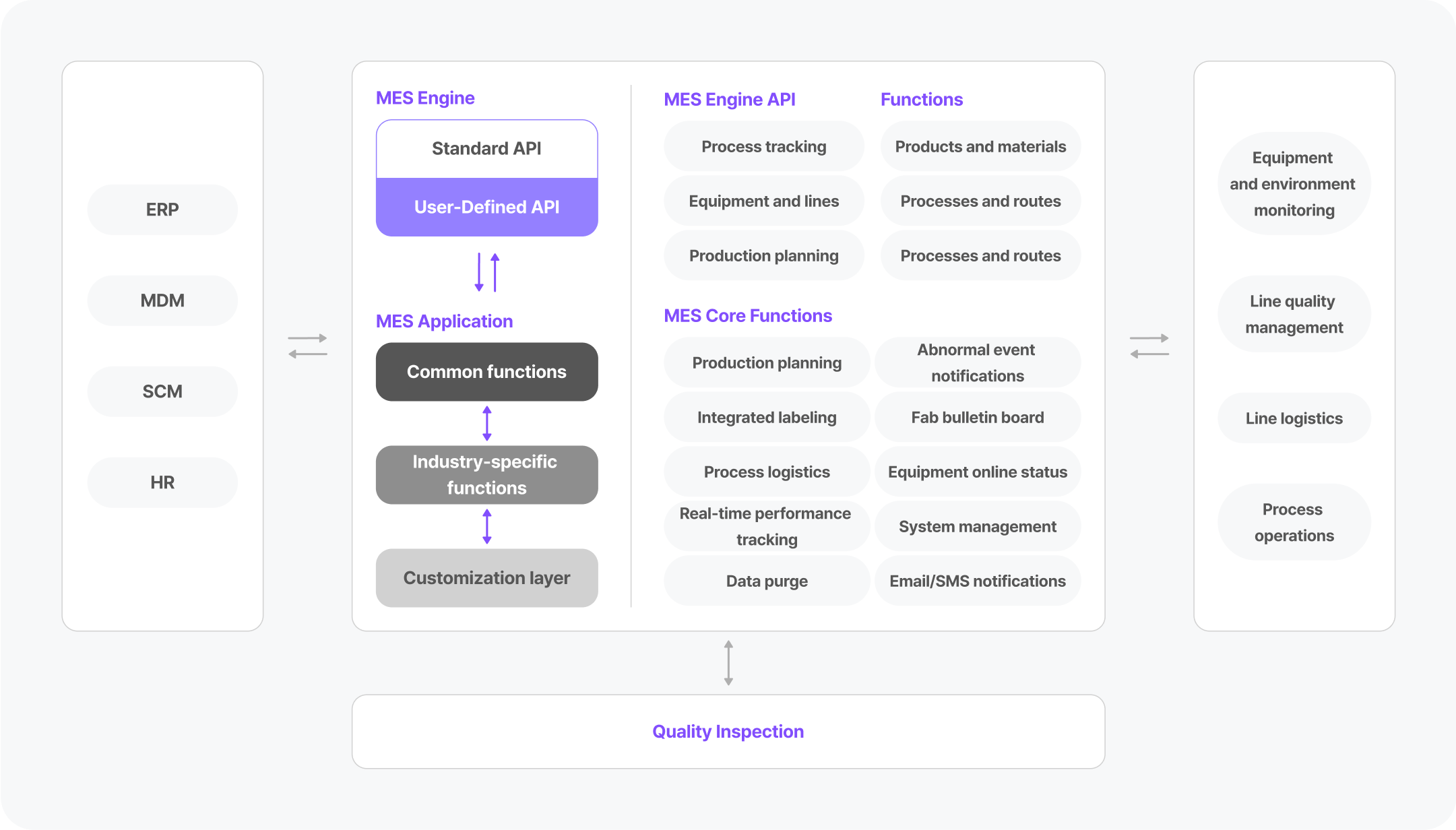

LG CNS has successfully deployed MES in various industries for more than 30 years, and Factova MES is a production execution system built on a proven track record. Based on the latest DX technology, it provides both standard and industry-specific functions for various manufacturing sectors, along with LG's extensive manufacturing industry know-how.

Provides LG's Extensive Manufacturing Industry Expertise

Providing MES Engine and Success Stories

System management, real-time monitoring, and label design functions

Providing Standard Processes for Each Industry

Process logistics automation, RTD, and online equipment functions

Providing Solutions for Process Management and Line Quality

Providing ECM Single Framework

Providing Standard Architecture and Development Environment

Modeling-based development tools and UI, web, and mobile standard development functions

Providing an Infrastructure Environment Flexibly Applicable to Various Manufacturing Environments

Multi-OS and multi-DBMS based operating environment

Providing Standard Interface Technology Between Systems and Equipment

Introducing a Solution for Two-Way Communication

Message-based middleware between equipment, between systems, and between applications within systems

-

Factova provides an integrated solution based on a standard framework, offering an embedded MES core for various industries—including petrochemicals, electronics, displays, pharmaceuticals, and batteries—which can dramatically reduce system implementation time. In addition, it features an ecosystem that is organically linked to the entire system—including MES, SPC, RMS, IoT, FDC, and QMS—providing a foundation for the easy utilization of AI and big data.

Moreover, real-time process data management maximizes manufacturing efficiency and improves both productivity and quality.

-

Implementing a production system is not merely about building a system; it is a comprehensive digital transformation (DX) process that spans the entire manufacturing operation. This process can be executed step by step. First, the client identifies issues within the manufacturing process and defines improvement requirements, then creates a process operation scenario. The company responsible for implementation subsequently identifies the client's pain points and assesses the level of smart factory maturity.

Based on this assessment, system requirements, introduction goals, and expected benefits are defined, establishing clear objectives and tasks. Change management and improvement activities must then be carried out alongside the system implementation. After the system is implemented, continuous monitoring of operational performance is essential to verify its effectiveness, and an upgrade and expansion strategy should be developed accordingly. This step-by-step approach not only ensures the stable adoption of the production system but also maximizes its value through efficient operation and continuous improvement.

and Innovate Logistics Based on Real-Time Data

Automated Inbound/Outbound and Inventory Management

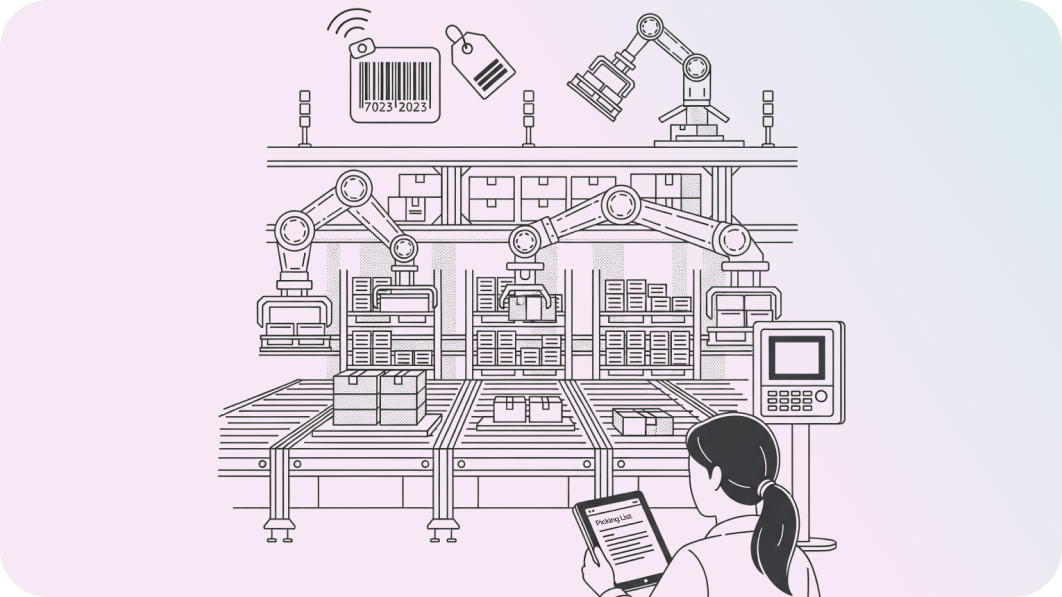

This feature provides automated inbound functionality using conveyor systems, robotic arms, and other equipment to store materials and products. It automatically identifies and records items using barcodes or RFID tags. It automatically places the inbound materials or products in designated locations.

It can plan and execute the release of materials according to requests from the production site or client orders. It also creates a picking list to provide workers with an efficient picking route. It provides accurate inventory information by tracking the location, quantity, and status of inventory in real time.

Data Analysis and Real-Time Monitoring

It supports efficient inventory management by analyzing inventory turnover, inventory levels, etc., and provides analysis features such as processing time for receiving and shipping, order processing accuracy, and picking efficiency. It monitors inventory quantity, location, status, and inbound/outbound work progress in real time to ensure operational transparency and improve bottlenecks or inefficient processes. It provides key performance indicators (KPIs) in real time through customizable dashboards.

Integration and Scalability

WMS's integration and scalability features support linking with various systems and a flexible response to changing business needs. It seamlessly exchanges data with the ERP system to synchronize order, inventory, and accounting information in real time. It integrates with TMS to optimize transportation planning, delivery tracking, and transportation cost management, and automatically coordinates outbound work and delivery schedules. It uses a standardized EDI format to automatically process orders, shipping documents, and delivery information by exchanging electronic documents with various partners. It provides accessibility in various regions to support global operations.

iWMS is a system that provides services for efficient inbound, outbound, and inventory management of materials, optimizing material flow and enhancing operational efficiency. It supports inbound/outbound and inventory management in automated warehouses using barcode scanners and RFID technology. It also enables accurate inventory level tracking through real-time inventory monitoring.

oWMS is a system that provides inbound, outbound, and inventory management services for product warehouses. It enables clients to provide fast and accurate services to their customers through accurate inventory tracking and management, automation of processes such as inbound/outbound handling, picking, and packing, and improvements in order processing speed and accuracy.

-

A WMS provides many benefits, including improved operational efficiency, increased inventory accuracy, cost reduction, improved customer service, and support for data-driven decision-making by systematizing warehouse and materials management.

Real-time performance tracking and material status monitoring help ensure consistency between physical inventory and the system. Integrating all aspects of material management into a single system improves overall work efficiency. In addition, strengthening interconnectivity between systems can simplify data sharing and further enhance operational efficiency.

-

When implementing a WMS, companies should first consider the scale and complexity of their operations. They must also evaluate integration with existing systems, standardization of operational processes, and user convenience.

-

Yes, a WMS supports multiple languages—including English, Chinese, Polish, and Indonesian—in addition to Korean, so it can be implemented and used at manufacturing and logistics sites both in Korea and overseas.