The growing use of technology in process management is accelerating digital transformation (DX), enhancing production efficiency and quality in manufacturing. In particular, advancements in the Internet of Things (IoT) enable real-time data collection and monitoring, increasing process transparency and allowing early detection of issues. Utilizing artificial intelligence (AI) and machine learning tools, businesses analyze process data, boosting productivity through predictive maintenance and process optimization.

The Recipe Management System (RMS) helps strengthen production quality control in manufacturing processes. By standardizing recipes, optimizing material management and production processes, RMS reduces human error and increases operational efficiency. As quality control becomes increasingly important, companies continue to expand investments in quality compliance.

and Remote Process Optimization Solution

The Recipe Management System (RMS) helps strengthen production quality control in manufacturing processes. By standardizing recipes, optimizing material management and production processes, RMS reduces human error and increases operational efficiency. As quality control becomes increasingly important, companies continue to expand investments in quality compliance.

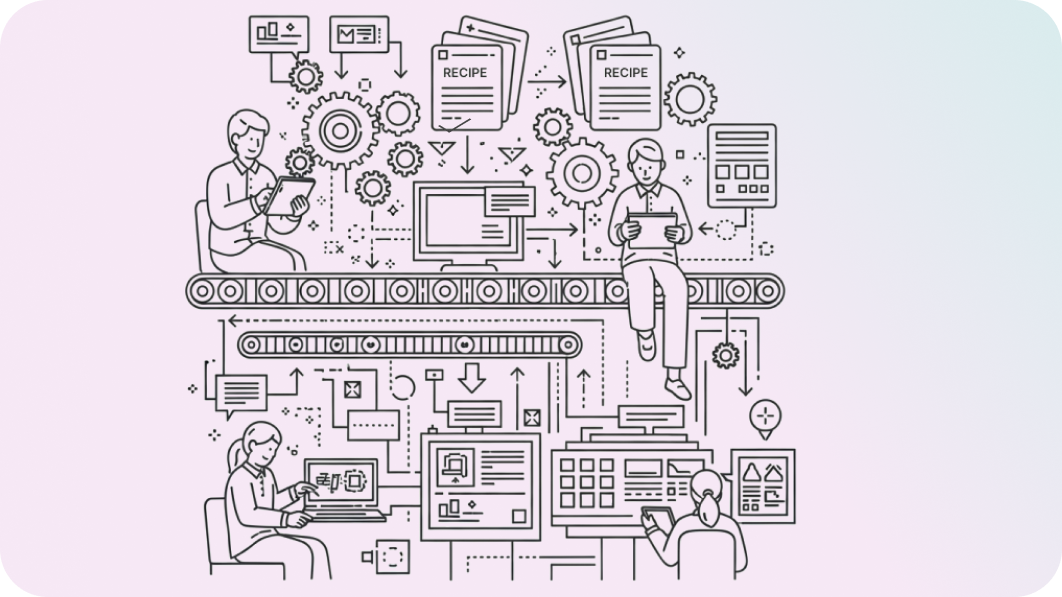

Process Standardization and Recipe Item Management

RMS systematically manages recipes by process, equipment, model, and version to help companies produce products of consistent quality reliably, regardless of the operator's career level or experience. This minimizes defects and increases efficiency by reducing recipe setup time. We provide the optimal solution that effectively solves the recipe management problems faced by many companies.

Checking for Recipe Misapplication and Preventing Quality Incidents

RMS automatically checks recipe settings by communicating with equipment in real time, and downloads and applies validated recipes. This helps prevent quality incidents caused by operator errors and avoid delivery delays, enabling stable fulfillment of client quality requirements.

Recipe Analysis and Optimization Support

RMS supports recipe analysis and optimization by linking product production history and quality data. Since past recipe settings are easily accessible, the optimal recipe for enhancing product quality can be identified, helping companies strengthen their competitiveness. To help companies meet their quality standards and client demands, RMS supports the creation of a smarter manufacturing environment.

RMS is an innovative manufacturing process management service that offers the following features. It supports recipe application history management, validation and interlock of equipment recipe settings, and automatic recipe setup on equipment (Download & Auto Apply). With these features, RMS helps companies produce products of consistent quality, enhances manufacturing efficiency, and provides a user-friendly interface that enables rapid process management on the manufacturing floor. Reduce manufacturing complexity and increase efficiency with the smart manufacturing solution, RMS.

-

The key consideration when implementing RMS is determining the scope of management for a factory’s products, processes, and equipment. Essential steps include identifying and clearly analyzing the products being produced, their processes, and the production-critical items of the process equipment; defining which items should be managed in RMS, and managing them systematically by recipe unit.

-

The effectiveness of RMS adoption is proportional to product diversity and process complexity. Greater product diversity and process complexity lead to increased variability in equipment settings and control values. Therefore, computerizing and managing these areas allows for improvements in productivity and reductions in defect rates. Thus, when introducing the RMS system, it is necessary to convince employees by presenting the expected benefits of RMS through a systematic analysis of the factory's products and processes.

Improved Quality Nonconformity Management

QMS supports the resolution of detected quality issues based on the 8D procedure through various inspection and test management functions.

It ensures visibility and traceability from the occurrence of quality issues to the completion of validation, and uses horizontal deployment and lessons learned functions to prevent the same or similar issues and avoid recurrence. It integrates quality issue management to enable easy review of the development and mass production quality history when issues occur, thereby facilitating quality improvements and client satisfaction.

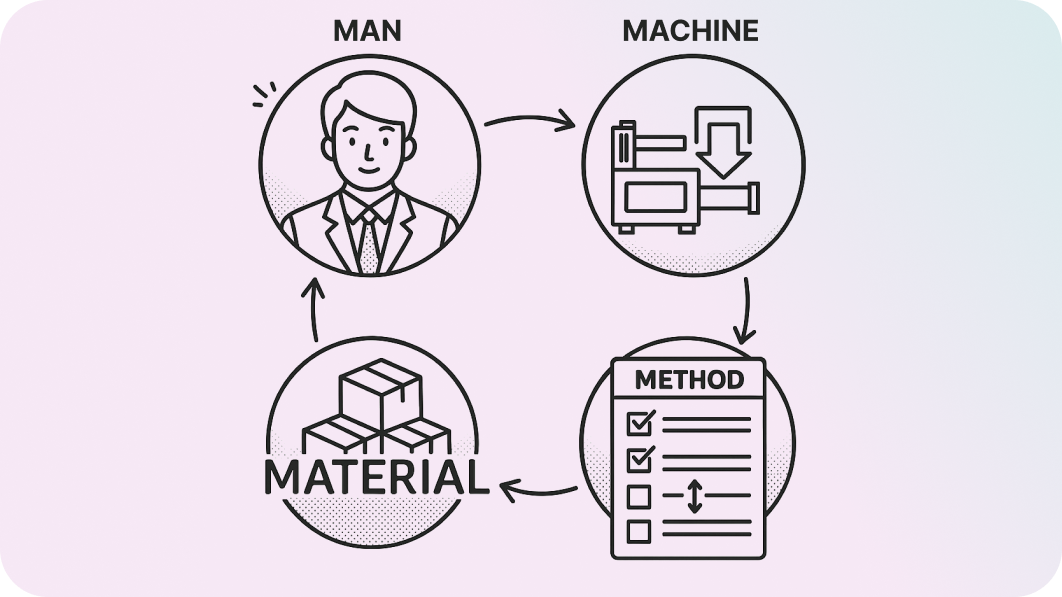

4M Change Control (4MCC)

The 4MCC system systematically manages the four elements of Man, Machine, Material, and Method to ensure product quality and safety. It helps prevent problems that may occur during production and ensure quality consistency through the stages of change request, review, validation, approval, application, evaluation, and history management. This maximizes the performance and reliability of the product and meets client requirements.

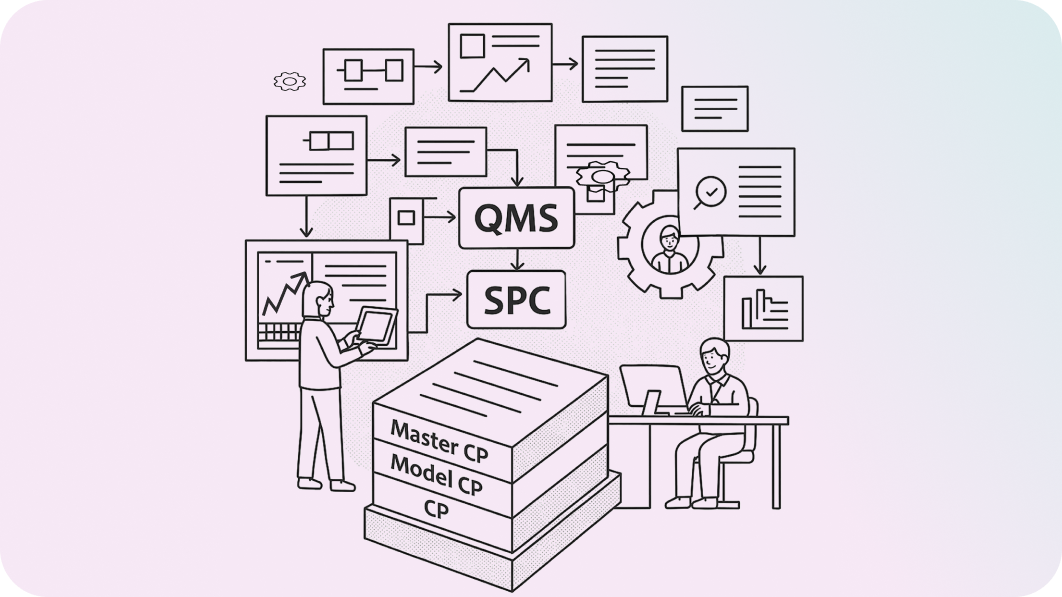

Process Development System (PDS)

The Process Development System (PDS) is a system that systematically establishes and manages the Control Plan for mass production to ensure production efficiency and quality, and deploys confirmed and changed information to related execution systems such as RMS, QMS, and SPC. The three control plans—Master CP, Model CP, and CP—manage the characteristics of each process and equipment information, thereby enhancing product quality and maximizing productivity.

Ongoing Reliability Testing (ORT)

The Ongoing Reliability Test (ORT) system is an innovative solution that automates the charging/discharging cell inspection process to maximize work efficiency and automates the issuance of test reports by linking inspection data. It ensures traceability of the risk range by auto-linking non-conformities to failed inspections, and provides reliable data to meet client evaluation items such as request, receipt, test, and results. This supports the success of clients' businesses and facilitates more accurate and thorough quality control and business process operations.

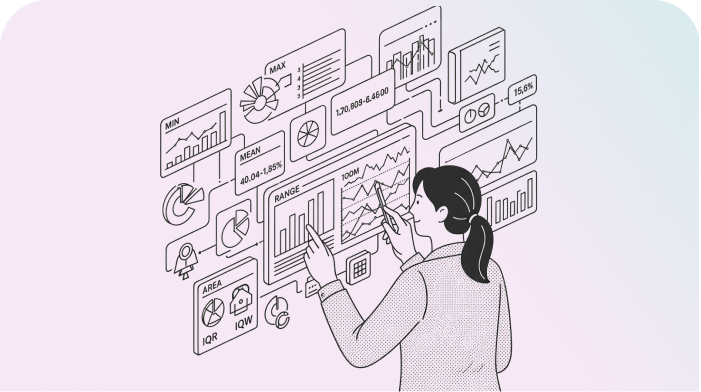

Through Real-Time Process Anomaly Detection of Inspection/Measurement Data

Automatic Collection of Inspection and Measurement Data and Images

We provide automated tools that can collect various types of inspection and measurement data in real time. his allows users to obtain the necessary information in real time from their office without visiting the site, and to verify the standardization and consistency of the data.

Additionally, inspection and measurement data are provided as visual information linked to images, allowing real-time monitoring of the inspection status, thereby streamlining the workflow from data collection to verification and enhancing work efficiency.

Real-Time Anomaly Detection and Interlock Control

In order to prevent product defects that occur during the manufacturing process, it is essential to quickly detect anomalies, share information immediately, and control them promptly. It must be possible to perform statistical analysis on the various data collected and to monitor in real time by applying an appropriate rule-based anomaly detection model. For any detected anomalies, the person in charge must be notified immediately and appropriate measures must be taken to halt the process. We propose a solution that can manage and resolve all these processes in an integrated manner.

Strengthening Capabilities for Stable and Evolving Process Operation

Securing process quality is not a one-time activity, but the result of continuous improvement efforts. This is due to the constant evolution of process technologies and equipment, and the presence of numerous variables in the process. To continuously improve process capability, it is necessary to engage in continuous calculation and management of process capability indicator (Cp) and process capability index (Cpk). For more efficient management, you can try flexible revision of the management baseline, prediction through simulation, and even automatic reflection of the control limits. Based on its accumulated experience and expertise, LG CNS can provide customized suggestions to help clients enhance their sustainable process capabilities.

It provides an agent with basic data collection functions, enabling quick system application. Customized deployment is also possible to collect data even from unique types of special equipment. It collects data in real time and performs precise analysis using R-based statistical analysis tools; in particular, inspection information is visually presented alongside the collected images.

It can detect abnormalities in real time according to Western Electric Rules, notify clients via their systems (e-mail, SMS), and also send interlock information to the Manufacturing Execution System (MES) to prevent further processing.

Image inspection using deep learning and AI can be performed automatically. It can be performed before and after inspections by professional inspectors to prevent defective products from escaping the process. And virtual inspection of products can be performed using measurement data. This can be used to reduce the burden of 100% inspection. This service is an information and image-based customized implementation service built within Factova SPCPlus.

-

The introduction of SPC, a statistical process control system, helps detect anomalies early and take appropriate countermeasures before a large number of defects occur. While producing high-quality products is important, enhancing process management capabilities to ensure consistent product quality is equally crucial. SPC supports the establishment of a sustainable quality management system by ensuring process stability and minimizing quality variation.

-

First, identify and define the Critical-to-Quality (CTQ) items to be managed. After establishing CTQ-specific management standards (specifications), confirm the processes and equipment that can collect data on the corresponding factors. Subsequently, with rule establishment and simulations, pre-validate the anomaly detection model for its specific application.

-

In SPC, anomaly detection begins by selecting the CTQ to be monitored and collecting the relevant data. Based on the collected data, statistical values are calculated and visualized to determine the anomaly detection range, or the anomaly detection range is selected first, followed by calculation and visualization of the statistical metrics. The limits for detecting anomalies are set through simulations using historical data, with reference to the Western Electric Rules, and a rule is established to automatically generate an alarm when an anomaly occurs. Upon detection of an anomaly, predefined response actions are applied, such as sending information to the MES or equipment to automatically stop operations, or immediately notifying the responsible personnel via email or text message.

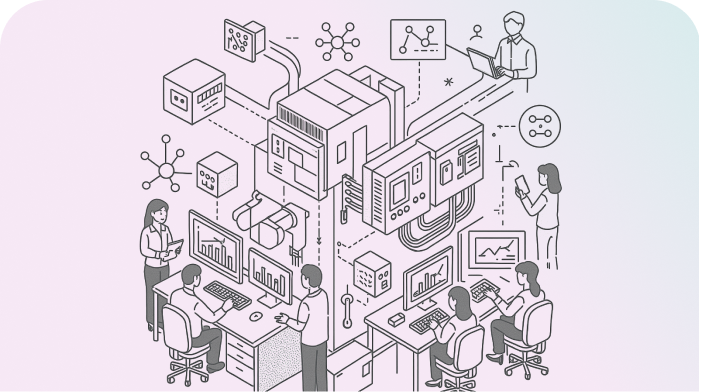

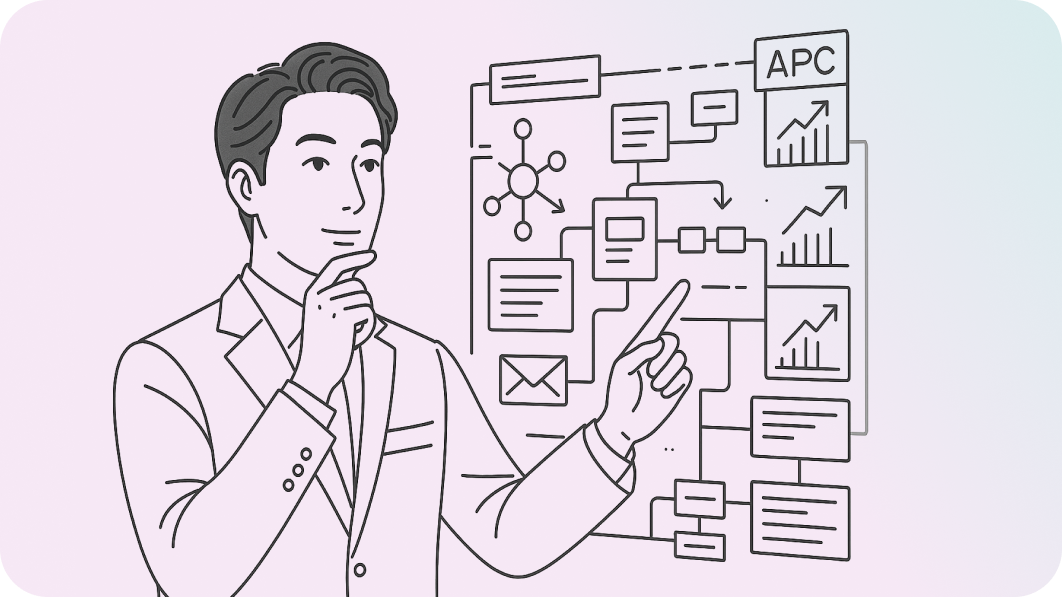

Comprehensive Solutions for APC

We have extensive experience in building Advanced Process Control (APC) based on process and equipment data from the entire factory. We can build a system that covers the entire process, from process and equipment data collection to anomaly detection, spread prevention, action, control, prediction, and prescription.

- Anomaly Detection/Spread Prevention/Control/Action: Data Collection (Factova)→FDC (E3)→ Process/Equipment Control (Factova), OCAP (UEngine)

- Anomaly Prediction/Prescription: FDC (E3), SPC (Factova)→VM (SI Development)→R2R (E3)→RMS (Factova)

Implementation Experience Across Various Industries

We have the optimal solutions for data collection and processing, and anomaly detection modeling for various industries, including displays, electric vehicle batteries, chemical cathode materials, and semiconductor substrates.

- IoT Data Collection and Processing (including various files, PLCs, messages)

- Industry-Specific Anomaly Detection Modeling (using general/virtual parameters and custom equations)

- Industry-Specific FDC Health Check Dashboards

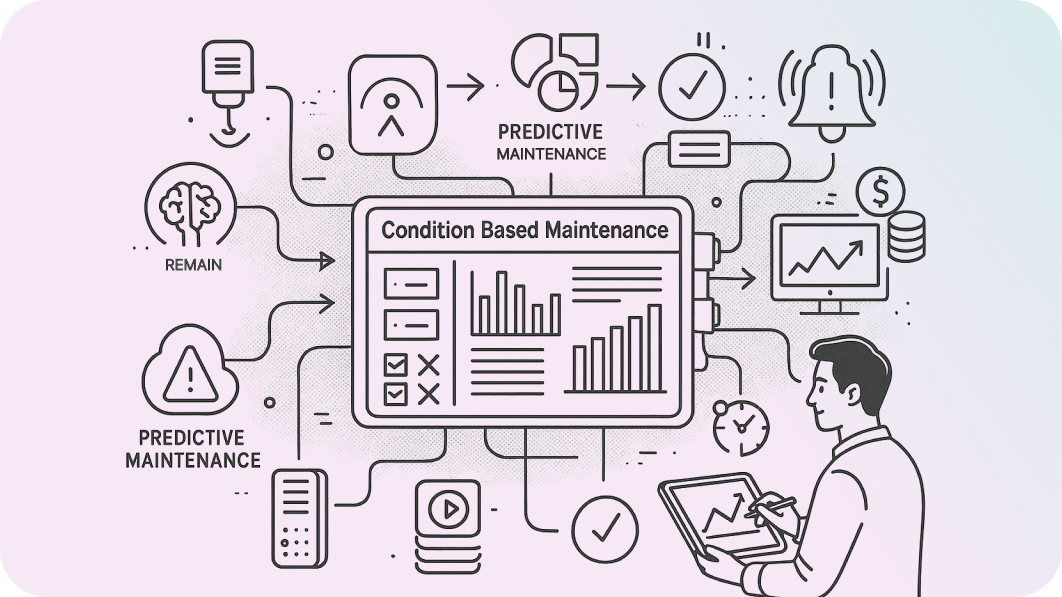

Predictive Maintenance – Run to Almost Fail

FDC-based condition-based maintenance (CBM) allows companies to flexibly determine the timing of maintenance based on the condition of the equipment. Furthermore, it calculates the remaining useful life (RUL) of the equipment to predict the possibility of equipment failure based on the future state and supports a predictive maintenance (PdM) function that enables maintenance to be performed at the right time.

In other words, pre-failure measures can be taken, preventing emergency situations, minimizing downtime, and significantly reducing maintenance costs while extending equipment life through accurate prediction.

-

When implementing FDC, you should consider both feasibility and the system implementation environment. To ensure the feasibility of FDC implementation through production loss analysis and to operate FDC efficiently, you should verify that your equipment provides an environment capable of collecting process data and related key parameters in real time.

-

Targets for anomaly detection should be selected based on the on-site engineers' experience and historical statistical analysis. Prioritize the key quality-affecting parameters, and use statistical techniques—such as feature selection—to identify additional significant variables.

-

Since FDC is based on time series data analysis, first select the interval where anomaly detection is required, and then choose the statistical metrics that best represent that interval. Set the anomaly detection threshold and establish alarm rules through simulations based on historical data to minimize false alarms. Prepare for immediate response by defining the interlock level that can automatically halt or control the process upon detection of an anomaly.