Digital transformation (DX) in product development has evolved beyond simple system implementation to become a key driver of innovation. Companies are actively adopting advanced technologies such as Artificial Intelligence (AI), big data, the Internet of Things (IoT), and the cloud to respond quickly and flexibly to market changes. For instance, by analyzing big data, companies can identify customer feedback and usage patterns to improve product quality. AI-based modeling enables the use of simulation during the design phase to detect errors early, reducing the cost of failure.

By leveraging virtual environments to replicate physical products and operations, performance and stability can be validated without building prototypes. When combined with simulation technology, errors can be detected and improved during the early stages. Cloud-based collaboration platforms enable real-time information sharing and decision-making across departments and regions, increasing development speed and agility. These advancements not only reduce time to market but also dramatically improve User Experience (UX). Furthermore, data accumulated throughout the product development process serves as a valuable asset for establishing R&D strategies and applying AI technologies. Through DX, companies aim to enhance product quality and efficiency while gaining a competitive edge and achieving sustainable growth.

Integrated Management of R&D Projects

Integrated management connects the entire R&D value chain—from roadmap development and early-stage research to external partnerships, product development, and mass production. This enables comprehensive management of project QCD (Quality, Cost, Delivery) on a single platform. In product development, LG CNS supports systematic management of integrated product data and efficient collaboration across mechanical, electrical, and software domains.

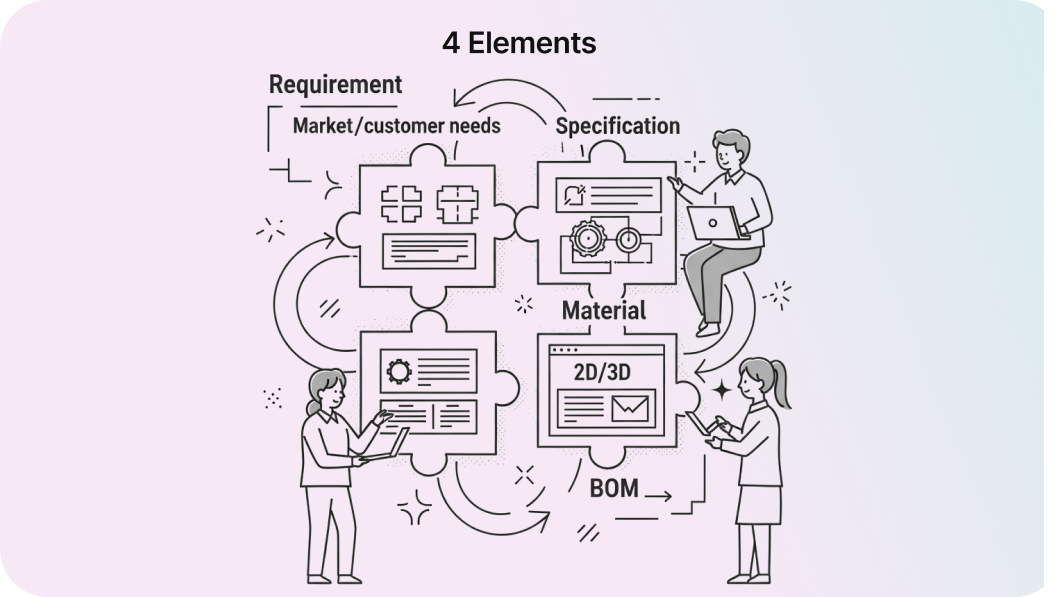

Systematic Management of Core Product Development Data (4 Elements)

Product development relies on four core data elements: Requirements (market/customer requirements, product/component requirements), Specifications (customer/product specs, functional/design specs, component/material specs, quality specs), Materials (components, raw materials, 2D/3D drawings), and BOM (Bill of Materials by purpose and application). These elements must be connected organically across the entire lifecycle—from requirement gathering and planning to design and mass production—and managed in a standardized manner. Strengthening connectivity and traceability in the Product Lifecycle Manament (PLM) End-to-End process enhances accuracy and consistency in development.

Customized Product Development Platform

LG CNS offers optimized product development platforms tailored to client environments by comparing and analyzing global PLM solutions and in-house development models. As a proven partner with experience across various manufacturing sectors—home appliances, batteries, automotive electronics, displays, chemicals, shipbuilding, and heavy industries—LG CNS brings domain knowledge and implementation capabilities to every project. With expertise in integrated diagnostics and deployment across the full R&D lifecycle, we deliver differentiated solutions powered by over 30 years of consulting experience and a dedicated team of PLM experts. Our systematic project management tools ensure deliverable quality, enabling us to provide best-in-class customized platforms.

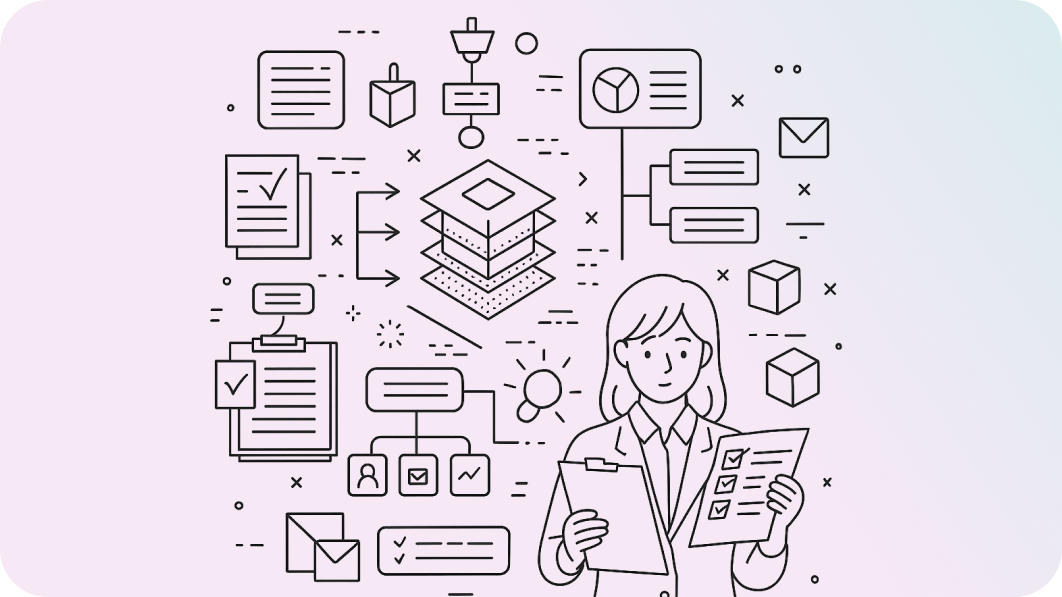

PDM registers and manages core product development information such as specifications, drawings, BOM, and standards, and shares the information across departments to manage the entire product lifecycle. It also controls access to and history of design data, establishing a structured data repository for AI learning.

LG CNS provides optimized solutions tailored to client needs, whether using global, domestic, or in-house platforms.

PMS enables real-time monitoring of enterprise-wide projects, allowing timely identification of issues and KPI assessment for root-cause analysis and resolution planning. It manages key project elements such as requirements, personnel, schedules, risks, goals, budgets, change history, and outputs. Through gate reviews, it enhances validation at each critical phase. LG CNS offers an integrated solution covering ISP, PI, system deployment, and maintenance to address common project management pain points.

ALM is an integrated management framework covering the full software development lifecycle, from requirement management and development to testing, issue tracking, deployment, operation, and monitoring. It promotes collaboration and standardization across development teams to increase project visibility and improve both speed and quality. Integration with PLM ensures connectivity between product BOM and software, enabling issue tracking of software versions throughout the production and development lifecycle.

-

Begin by analyzing the client system environment and cost structure to determine whether upgrading the existing solution or building a new in-house system is more effective. Consulting with an experienced partner can help identify the optimal transition strategy, including phased migration plans if needed.

-

For efficient drawing management, using the PLM solution provided by the CAD vendor is typically recommended. If multiple CAD systems are used, we suggest adopting CAD middleware tailored to each CAD environment and integrating it with an in-house PLM to manage standard PLM functions such as BOM and ECO (Engineering Change Order).

-

By referencing the R&D PLM maturity model derived from the R&D IT maturity model, LG CNS can assess our client’s current capabilities and define improvement directions and strategic initiatives. This enables a practical roadmap for PLM implementation and establishes a solid foundation for DX initiatives.

-

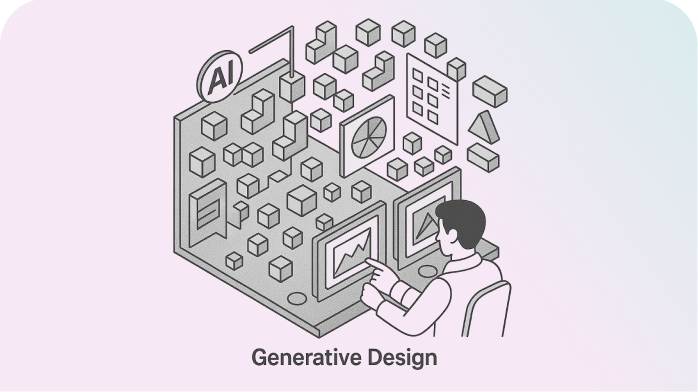

Identify areas within the development process where AI application can be effective. Then explore feasible applications through case studies and jointly develop PoCs to validate their impact. LG CNS operates Innovation Studio, which offers access to diverse AI references aligned with the client’s industry. Through collaboration, we propose tailored strategies to enhance agility and productivity in product development.

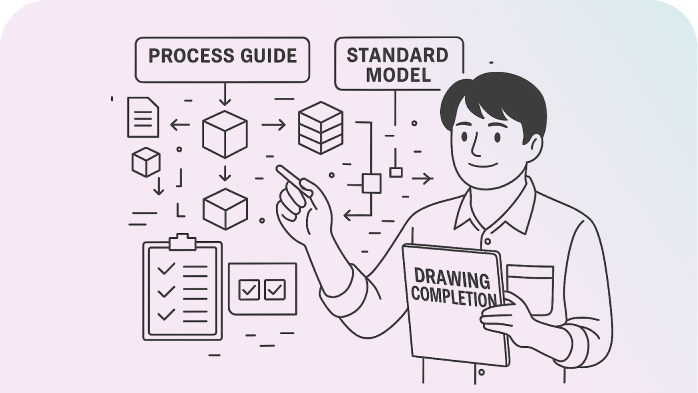

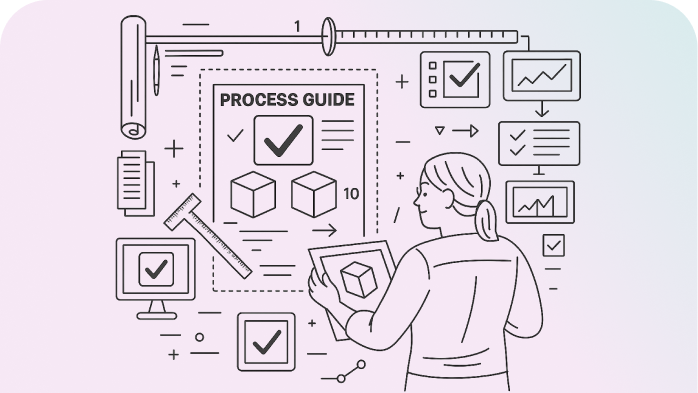

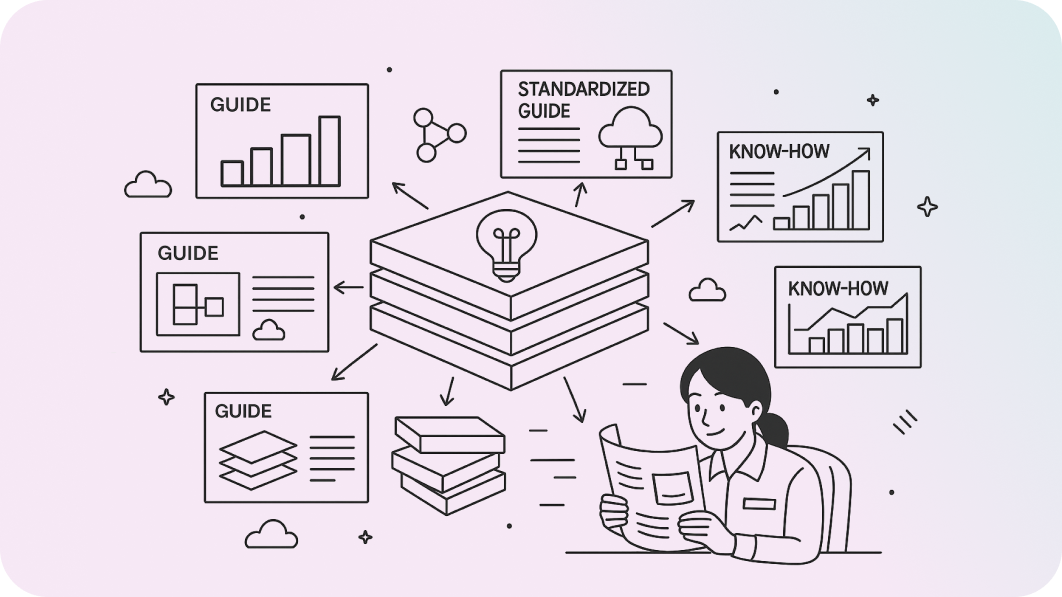

Standardized Design Process

We offer a standardized design process to reliably accumulate and efficiently manage various types of data generated during product design. By clearly defining the criteria and procedures to apply from the initial development stage, we ensure quality checks and consistency throughout the entire process. Issues identified during development or prototyping are continuously updated in guidelines and checklists to maintain consistent quality.

Design Data-Based Product Development Environment

We provide standardized development guides at each stage of the process based on accumulated design data and expertise. The structured framework allows even new engineers to follow the process with ease, enabling efficient execution from early-stage design to drawing completion. By delivering a standardized design environment, we help secure consistent design quality from the outset.

AI Coworker

AI plays a key role in analyzing design data and generating insights during design and validation. Time-consuming and complex tasks such as reviewing drawings or analyzing simulation results can be handled efficiently by AI models, which detect irregular patterns and suggest optimal design outcomes. AI also helps automate design tasks, reducing development time and identifying risks or errors early, contributing to higher product quality. This enhances competitiveness and significantly increases market responsiveness.

Design Navigator is a design support system that guides the entire process from initial planning to drawing completion. It offers step-by-step procedures and best practices for each phase of design, allowing anyone to carry out consistent and optimized design tasks. The system streamlines workflows, shortens project timelines, and improves design quality through system-based validation. With Design Navigator, even junior designers can start designing with confidence.

Design Navigator AI moves beyond traditional design and validation by offering an AI-powered intelligent design environment It generates new models based on existing designs. Through real-time validation and simulation, it contributes to design quality and shortens design time. Additionally, it enables easy access to product data through chat-based search.

-

Design Navigator provides context-specific guidelines and data required for each stage, enabling designers to work optimally. However, to ensure effective operation, it's important to define standard processes and design guidelines concurrently. Initial implementation includes the development of standards and a framework for managing reference information, ensuring a stable system rollout in phases.

-

Design Navigator supports various domains including mechanical, electrical, and product design. We analyze our client's environment in detail, streamline workflows, and build automation modules tailored to each case. With broad industry experience, we deliver optimized environments that enhance both efficiency and design quality.

: Always-Available, Optimized Product Development Tools and Environments

Data integration and efficient management are essential to innovation in R&D. C4 Cloud connects design and simulation data to create an optimized environment for research and development. It integrates high-performance computing (HPC) resources and research software data within the organization, providing researchers with an IT infrastructure service environment to easily access R&D resources anytime, anywhere via the Internet. This improves productivity, streamlines resource management, and strengthens technical documentation. As demand increases for AI and data-intensive R&D, the role of HPC infrastructure becomes more critical. Future C4 Cloud data centers will require not just processing performance (CPUs, GPUs), but also enhancements in power efficiency, density, and supporting infrastructure such as servers, networks, and cooling systems.

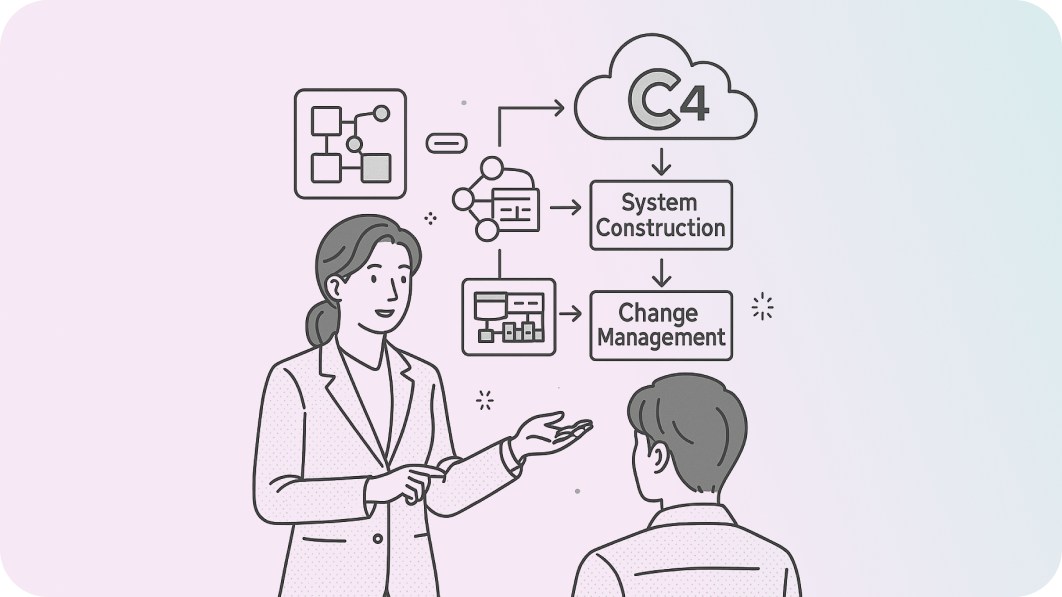

System Deployment Services

Backed by extensive experience with in-house LG Group systems, LG CNS provides consulting and deployment services for C4 Cloud. The deployment process includes hardware/software analysis, license integration, system setup, change management, and optimization. Our step-by-step deployment expertise ensures comprehensive support.

Successful deployment requires software integration across multiple systems. Based on client requirements, we propose software integration plans and execute deployment aligned with the latest IT technologies.

System Operations Services

Our integrated operation services ensure stable management of both large- and small-scale environments. While operating C4 Cloud requires a broad skill set, smaller sites often face challenges securing dedicated staff. To address this, we offer optimized, cost-effective integrated services without blind spots in operations.

C4 Cloud provides infrastructure resources across the product development lifecycle, including GPU VDI for CAD, preprocessing, and post-processing; high-performance CPU for simulation calculation; ML/DL data analytics; and development/test environments for software and models.

EN_064_PLM_img_01.png)

EN_064_PLM_img_01.png)

-

The key is software integration. Researchers prefer familiar tools, so compatibility is essential. Integration is a complex and time-consuming process, but it can succeed with a user-centric approach and well-planned strategy. Training and promotion of new tools are also vital.

-

C4 Cloud accelerates the digital transformation of the R&D environment. It provides flexibility in working time and location, reduces unnecessary license investments, and enhances data security. It also eliminates the time and effort required to individually manage workstations, allowing researchers to focus on core development tasks.

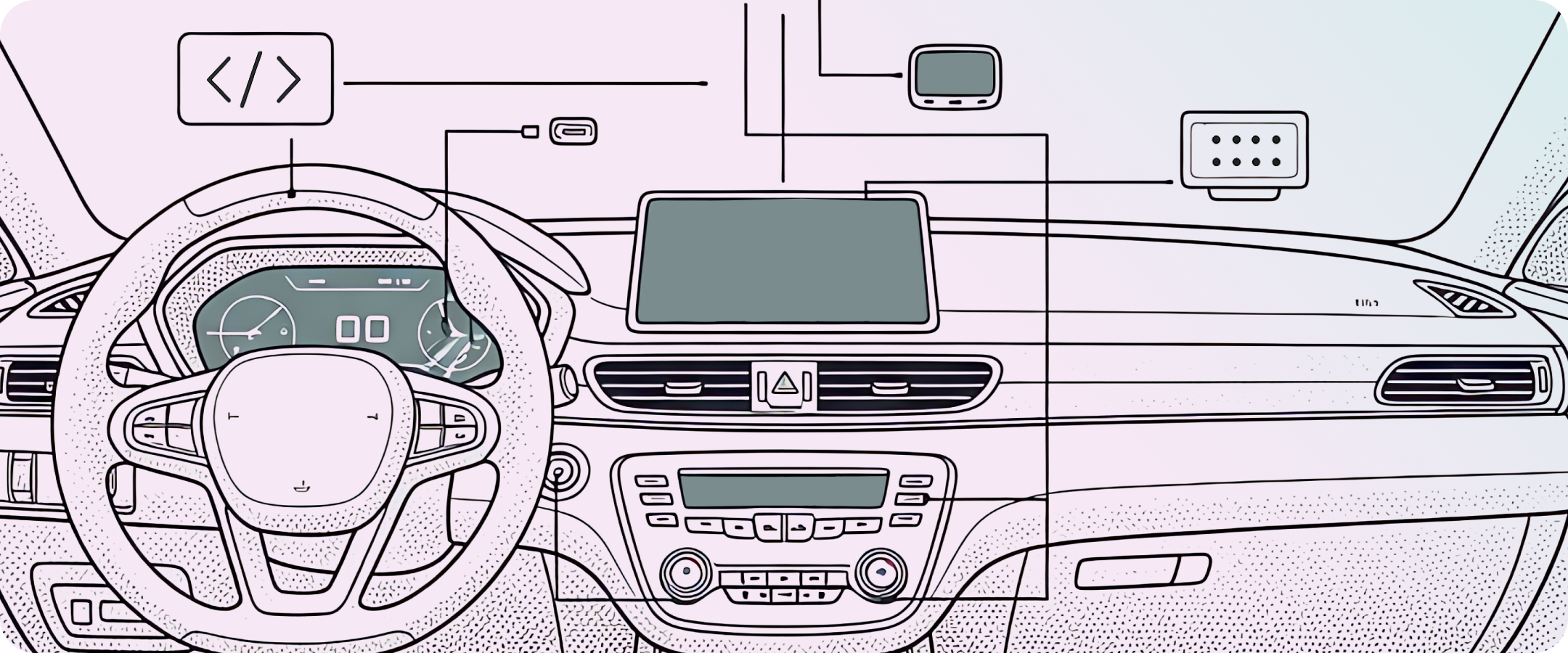

Delivering Diverse, High-Quality Infotainment

In-vehicle infotainment functions integrated into AVN (Audio, Video, Navigation) systems are expanding in scope and sophistication. These include radio, DMB, smartphone mirroring (Android Auto, Apple CarPlay), Car-to-Home and Home-to-Car connectivity, remote climate and start controls, weather/sports/calendar sync, and in-vehicle payments. Entertainment services are also being enhanced to consolidate diverse media content.

LG CNS offers full-stack development and maintenance from service to application layers, including consulting.

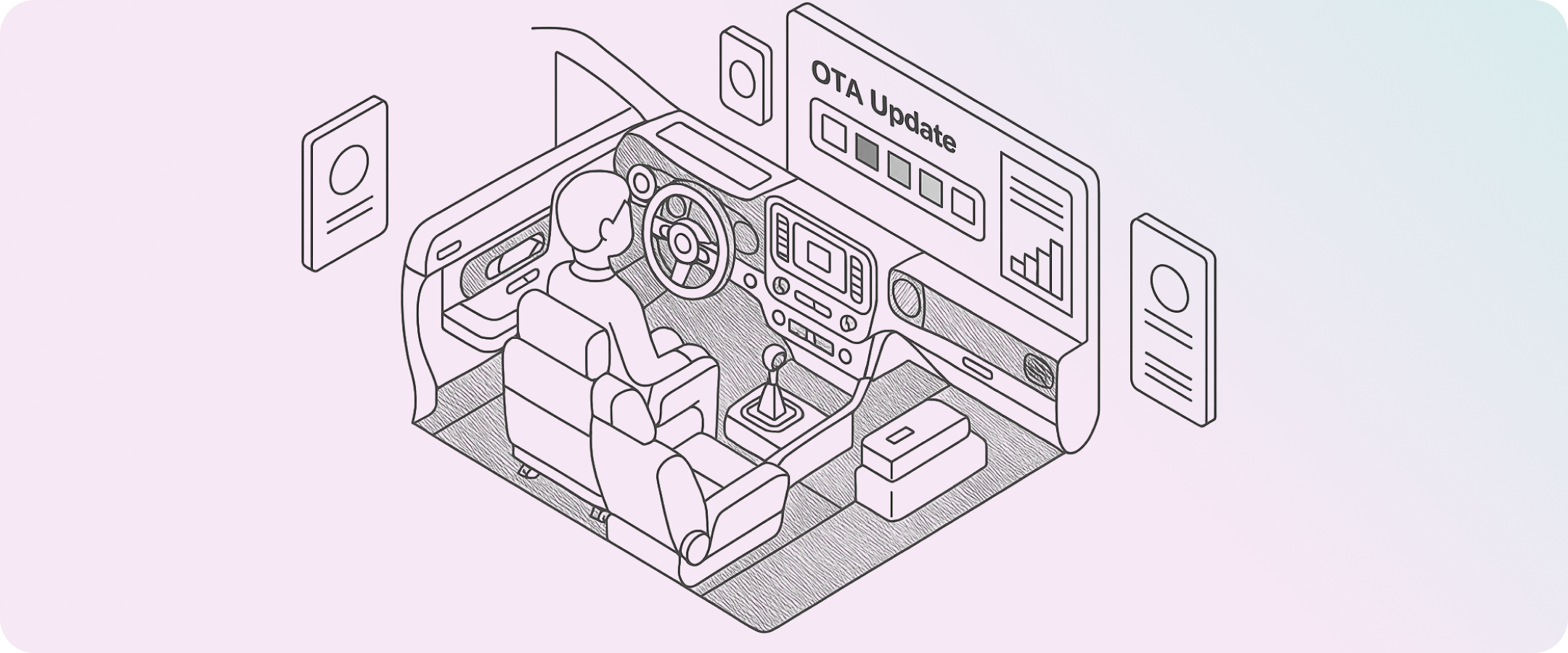

We also provide OTA (Over-the-Air) update capabilities to keep vehicles up to date without service center visits.

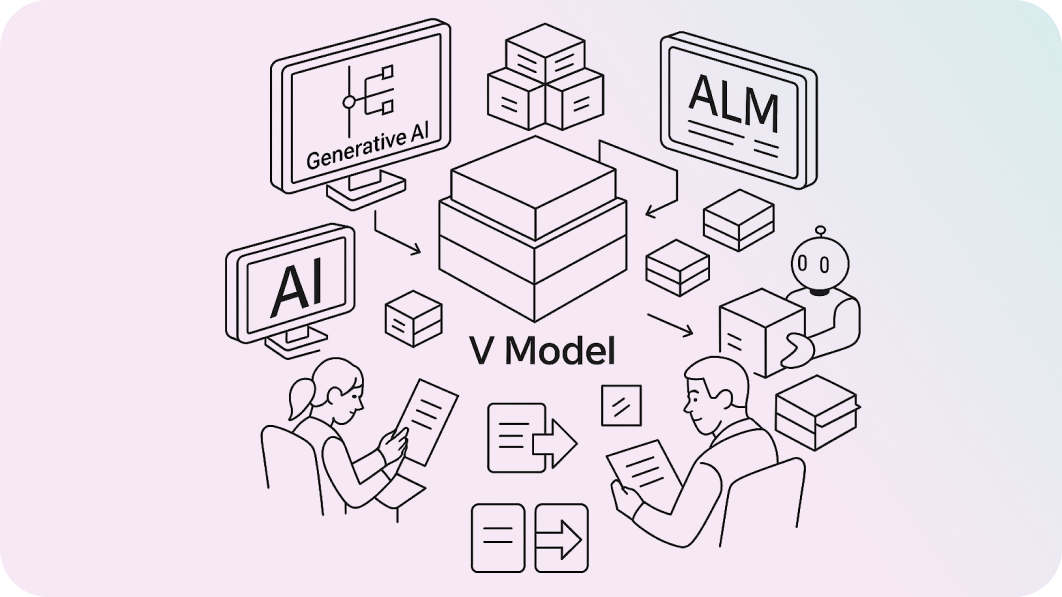

Boosting Efficiency with Generative AI in Automotive Software Development

Automotive software development is becoming more complex, and Generative AI plays a crucial role in enhancing productivity and quality.

Traditional V-model development (analysis, design, development, testing) supported by ALM (Application Lifecycle Management) tools still relies heavily on manual processing of large, unstructured documents. Tasks like search, document classification, review, analysis, and writing are prone to inefficiencies and human error. By integrating Generative AI, repetitive and unstructured tasks can be automated, accelerating document handling and boosting accuracy. This makes the overall development process more efficient and advanced.

It also enables consistent quality across client projects, supporting higher productivity and software quality.

We develop AVN infotainment functions including radio, DMB, CCS (remote climate/start, Car-to-Home, Home-to-Car connectivity, weather, sports, calendar sync, in-vehicle payments), Android Auto, and Apple CarPlay. We also develop integration features for devices such as clusters, HUDs (Head-Up Displays), and climate systems. Key entertainment content for SDVs includes audio streaming services such as Genie, Melon, Naver Vibe, Welaaa Audio, Amazon Music, SoundCloud, and Spotify. We support media streaming services like Netflix, YouTube, and LG Channels on in-vehicle webOS platforms.

OTA updates are a core component of SDVs, enabling wireless software updates while saving time and cost by keeping vehicles up to date without the need for service center visits. LG CNS works with LG Electronics to deliver OTA solutions applied to Hyundai vehicles.

The rise of SDV is driving demand for faster software development from OEMs. Manual code reviews and self-validation are often too time-consuming to meet tight deadlines, ultimately affecting software quality. Generative AI helps address these challenges by automating code review and validation tasks. LG CNS provides solutions to support faster, higher-quality software development.