Recently, digital transformation (DX) in production logistics management has emerged as a key factor determining manufacturing competitiveness. Applying IT technology allows for real-time data collection from production lines. This enables the automation and optimization of factory logistics, enhancing productivity and strengthening manufacturing competitiveness. Data- and system-based decision-making is increasingly vital in production logistics operations. Consequently, companies are introducing logistics automation systems driven by artificial intelligence (AI) and optimization technologies to reduce costs and improve productivity.

In order to respond to the rapidly changing market environment, technological advancements, and the diverse client needs, the manufacturing industry is also demanding faster and more flexible production line response capabilities. Accordingly, investments are continuously expanding. These investments aim to enhance flexibility through IT system implementation, increase productivity via automation and optimization, and enable swift responses to market changes.

RTD (Real Time Dispatcher) is a solution that determines in real time the priority of products and materials to be used for the next task and the logistics movement conditions for each production equipment. It provides an intuitive workflow-based configuration tool to manage complex task and logistics movement conditions as rules. It supports accurate control of the logistics flow and improvement of operational efficiency by simultaneously implementing standardization and automation of production logistics operations.

MCS (Material Control System) is a solution that automates logistics movement by supporting everything from route search to the integrated control of various logistics equipment such as AGV (Automated Guided Vehicle), OHT (Overhead Hoist Transport), conveyors, and stockers, thereby streamlining production logistics. It also supports standard interfaces such as HSMS/GEM and equipment communication standards such as SEMI IBSEM and STKSEM, providing various setting functions to fix or change the logistics movement route. This optimizes the flow of logistics within the factory and improves productivity.

-

To introduce RTD (Real Time Dispatcher), first gather feedback from production site managers and analyze the equipment operation status to develop work rules and operational scenarios for each production equipment, and implement these rules accordingly. It is also important to establish a system that can continuously incorporate the know-how of production site managers.

Introducing MCS (Material Control System) requires assessing current logistics equipment operations and establishing detailed interface specifications. Close consultation and cooperation with logistics equipment vendors are essential to implement a standardized interface model. Based on these steps, it is possible to build an integrated logistics equipment control system. -

Introducing RTD can standardize and automate the selection of products and materials for subsequent processing and issue logistics movement instructions for each production equipment, thereby reducing operational losses caused by human error and improving both equipment productivity and operational efficiency.

The effect of introducing MCS is that the implementation period for logistics equipment can be shortened and stabilized early through the standardization of equipment specifications. Overall production efficiency can also be improved by reducing the idle time of production equipment through shorter logistics movement times. -

Yes. Even in manual handling environments without dedicated logistics equipment, the RTD and MCS user interface (UI) helps operators make optimal decisions about which products and materials to move and where.

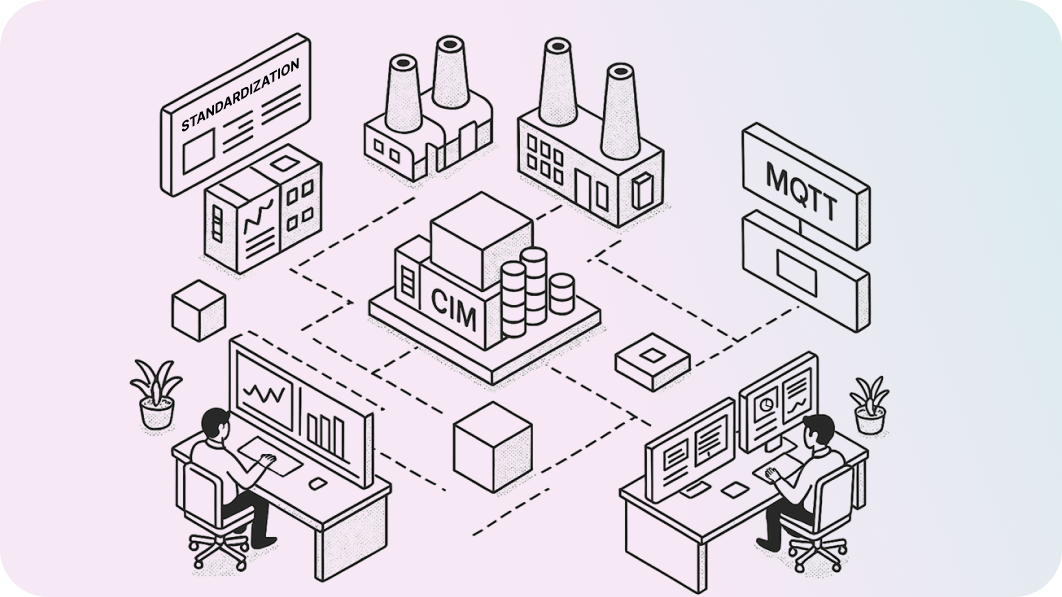

Standardized Equipment Control and Operation Optimization

LG CNS's Computer Integrated Manufacturing (CIM) service maximizes operational efficiency through standardized control and data integration among various equipment. It supports equipment interfaces with the latest technologies such as OPC UA (Open Platform Communications Unified Architecture) and MQTT (a standard publish-subscribe-based messaging protocol), and enables flexible process operation through modeling-based equipment configuration. In addition, it effectively solves operational complexity by strengthening the connection with the upper-level system (MES) through standardized data management.

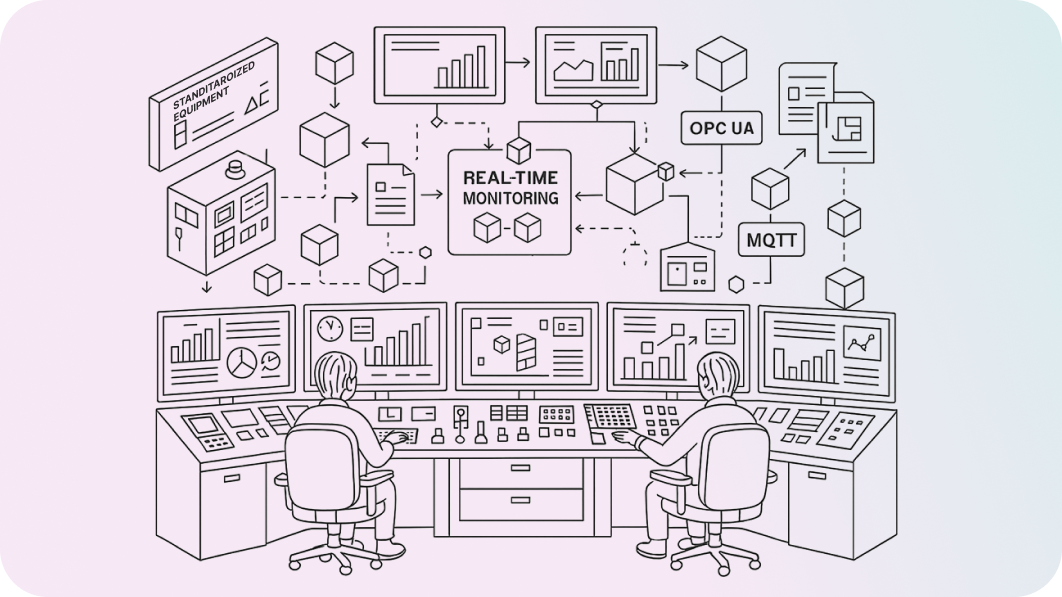

Real-Time Monitoring and Uninterrupted Operation Environment

LG CNS provides an environment that allows companies to understand process status in real time and respond quickly to emergencies through real-time monitoring and control systems. Non-disruptive business logic patches maintain operational efficiency without interrupting the production process, and integrated data flows among various equipment support optimal decision-making using real-time data.

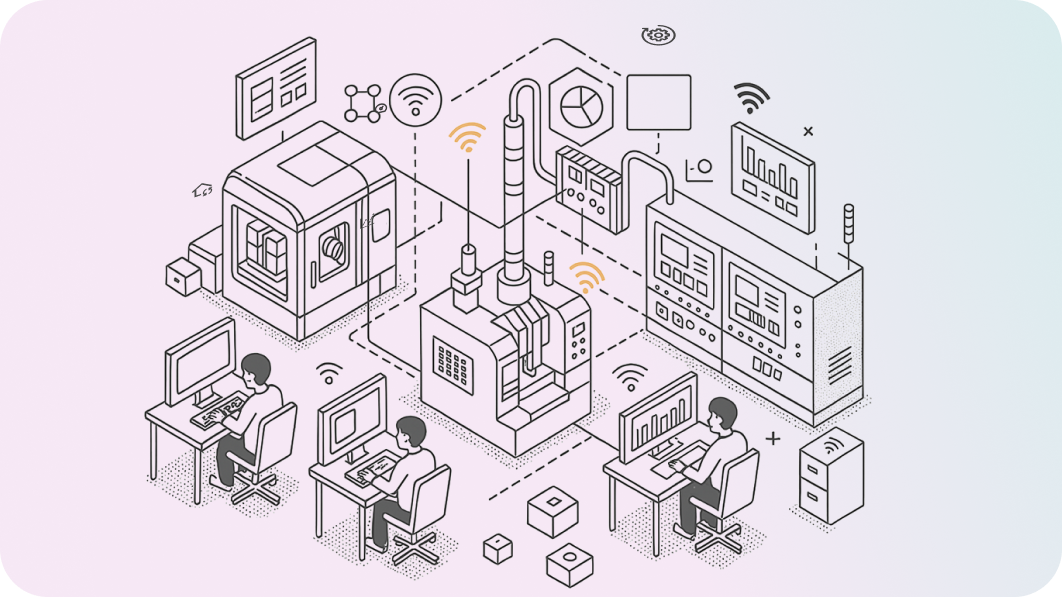

Reducing Equipment Complexity and Enabling Flexibility

At manufacturing sites, operating efficiency is being hindered by equipment control specifications that differ by manufacturer and upper-level system connection issues. LG CNS's CIM service addresses this complexity through standardized equipment control and support for various interfaces (OPC UA, MQTT, etc.). In addition, it flexibly manages devices and I/O (input/output) through modeling-based equipment configuration, intuitively monitors process status through real-time data connection, and provides an optimized operating environment.

-

- Utilize In-Memory Processing-based high-speed processing; Collect real-time equipment data

- Provide various services for production, logistics, and environmental equipment control and automation

-

- Enable flexible, modeling-based equipment configuration, including device input/output

- Easily reuse and reconfigure using component-based control modules

-

- Support PLC and Fieldbus standards (Siemens, Mitsubishi, LSIS, Omron, OPC, etc.)

- Support various message protocols such as HSMS and Solace

-

- Patch business logic in real time without interruption, even when the equipment is in operation

-

- Support integrated monitoring tools (such as real-time process information, driver status, input/output values) and management tools (for process monitoring, deployment, and patching)

-

If the control specifications differ between equipment, it is effective to introduce a system that supports standardized equipment control and standard data communication (OPC UA, MQTT, etc.). This ensures compatibility between equipment and creates a flexible and efficient operating environment through modeling-based equipment configuration.

-

By introducing a platform that can integrate and manage various automated control equipment (Programmable Logic Controller, PLC) and fieldbus interfaces, the equipment interface can be efficiently linked with other systems. This also resolves integration issues with the upper-level system (MES) and enables real-time data flow, thereby increasing the efficiency of process management.

-

If you use a system that provides real-time data collection and is based on a standardized data management framework, you can integrate your process data with upper-level systems. This enables real-time monitoring, analysis, and prediction-based process optimization.

-

A system that provides a real-time business logic patch feature allows modification of the process control logic without interrupting production. This maintains a stable production environment and ensures operational efficiency.

-

A system that includes real-time process monitoring and control features offers a visual, intuitive dashboard and notification system that immediately conveys process status, enabling quick and accurate responses in emergency situations.

– The Foundation of Smart Factory Implementation

The various pre-built communication drivers built within the solution allow for quick interpretation of manufacturer-proprietary protocols and rapid data collection without the need for separate development. In addition, if the manufacturer does not provide software for protocol interpretation during a system implementation project, custom interpretation software can be developed and used through separate development efforts.

The module provides a structure that facilitates direct command delivery to equipment PLCs based on collected data and scenarios for production and logistics control. The equipment control scenarios are tailored and optimized according to each client's operational methods and requirements, and custom SI implementation logic can be applied based on the provided module.

Binding data to screen elements is easy, allowing intuitive visualization of collected data, and the monitoring system can also be implemented through modeling alone without any additional development.

-

PLC communication drivers from major manufacturers such as Mitsubishi, LS Electric (formerly LSIS), Omron, and Siemens are built in, allowing easy modeling and data collection.

-

The collected data is transmitted to the upper-level system through middleware and is not stored in the collection area by default. However, in cases where there is no upper-level system or under special circumstances, data can be temporarily stored in the collection area through SI development.

-

By default, we do not convert every manufacturer's protocol into a reusable asset. Therefore, if development is required, data must be collected through SI development, and technical support is available for this process. However, for widely used manufacturers, we develop and provide communication drivers as reusable assets.

Maximizing Data-Based Operational Efficiency

The key resource for virtual equipment validation is the effective collection and utilization of the vast amounts of data generated by the equipment. LG CNS has been collecting equipment sensor data and operational data through its extensive experience across various industries and leveraging cross-departmental collaboration for analysis and utilization. In virtual equipment validation, data generated by the equipment and factory are collected, analyzed, and used as simulation parameters to emulate the behavior of the actual equipment, thereby pre-validating various cases that may occur during operation.

Reducing Initial Implementation Costs Through Rapid and Efficient Deployment

Virtual equipment validation plays a major role in maximizing a company’s efficiency, but the initial introduction costs can be burdensome. LG CNS supports faster and more efficient implementation based on the know-how and assets accumulated from numerous virtual equipment validation projects. It helps to utilize data consistently by applying a standardized validation process and significantly reduces implementation time by reusing existing assets in new simulations. This approach not only reduces costs but also enables a faster and more flexible digital transformation.

Building an Efficient and Smart Virtual Equipment Validation Environment

Based on its extensive project experience and assets, LG CNS efficiently collects and analyzes data from existing equipment through inter-departmental collaboration to build a fast and efficient virtual equipment validation environment. It applies standardized processes proven across various projects to ensure consistent results and uses AI and IoT technologies to optimize equipment performance. In addition, the predictive maintenance feature enables the early identification of potential equipment failures and supports preventive maintenance to ensure stable operation.

LG CNS provides three core services through virtual equipment validation.

First, production plan validation identifies target production volumes and detects potential logistics or equipment issues in advance, helping prevent problems during the production process.

Second, it optimizes operation scenarios for equipment and processes to maximize efficiency and improve resource utilization.

Third, by using actual data to validate abnormal cases and predict problems, unexpected downtime and increased costs can be prevented.

This approach supports productivity improvement and cost reduction, ultimately strengthening the company's competitiveness.

-

Virtual equipment validation enables companies to pre-optimize equipment performance and anticipate potential issues, thereby enhancing productivity and reducing unnecessary maintenance costs. Moreover, when modifications or improvements are required, companies can virtually analyze and optimize various scenarios without impacting actual equipment, ensuring efficient management without operational interruptions.

-

The first step is analyzing the equipment and systems currently in use at the client’s site. Based on this analysis, we define the requirements that align with the client's operating environment and objectives, and then design a customized virtual equipment validation solution that can be implemented efficiently and successfully.