As client orders become increasingly segmented and diversified, and expectations for delivery services—such as same-day and weekend delivery—rise, logistics capabilities in the retail industry have become directly tied to corporate competitiveness. To meet these evolving client demands, companies have been ramping up investments in logistics automation. Recently, retail companies have been expanding their focus beyond automation to full-scale unmanned operations in response to labor shortages, rising labor costs, and the need for 24/7 logistics center operations. Furthermore, to enhance logistics center efficiency, the industry is increasingly incorporating AI, IoT, and computer vision into automated equipment for intelligent operations. At the same time, leveraging data collected from logistics equipment for optimization, enabling meaningful insights and decision-making support, is gaining importance.

To swiftly adapt to dynamic business environments and evolving client needs, retail companies are prioritizing agile logistics automation solutions. Modular equipment and logistics robots are gaining traction as they enable rapid deployment and seamless scalability. Notably, to facilitate faster adoption, verification, and to ease the burden of initial investment, more companies are turning to the Robot-as-a-Service (RaaS) model.

Logistics Consulting

There is a wide variety of automation equipment that can be integrated into logistics centers. Even for transport systems alone, options range from fixed conveyor systems to Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). The role of logistics consulting is to assess the constraints of each system while considering the client’s business environment to recommend the optimal combination of automation solutions.

LG CNS has extensive consulting experience across various industries and provides tailored consulting services by continuously engaging with clients to align with their business needs.

-

One approach is to start with consulting on a smaller scale. Instead of automating the entire logistics center, consider first reviewing, selecting, and implementing automation equipment in areas that appear to have high efficiency. Once the actual effectiveness is verified, automation can then be expanded to the entire process based on these results.

LG CNS is advancing existing automation-focused Hard Warehouses into Digital/Data Warehouses through its smart logistics platform, which applies IT innovations such as optimization algorithms, digital twins, IoT, and AI.

Optimization Algorithm

Analyzes accumulated order data to determine the optimal product supply sequence within the logistics center. It also applies a Tetris-like stacking method to tote boxes, maximizing the number of products transported in a single trip.

AI Cargo Classification

AI recognizes the shape of items and classifies them into three types—large, medium/small, and irregular—enhancing worker productivity.

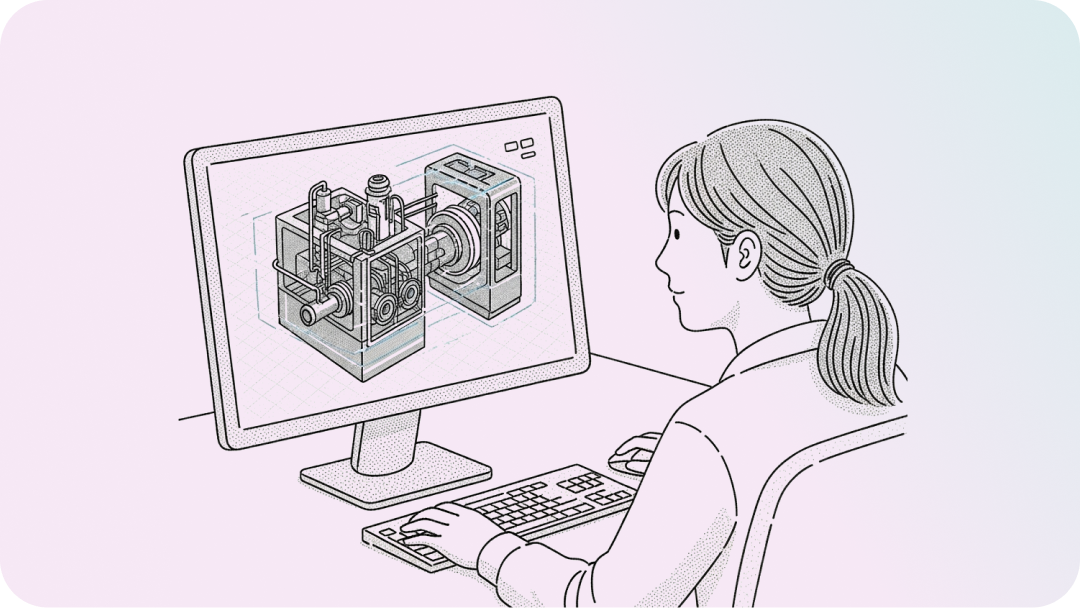

Digital Twin

Replicates physical equipment in 3D on a computer monitor, enabling immediate inspection for any malfunctions.

-

If business volatility is high, adopting flexible and modular solutions like logistics robots can be a viable option. A growing trend in both domestic and global markets is adjusting the number of deployed robots based on fluctuations in demand. Additionally, optimizing logistics center operations can help maximize efficiency and minimize the impact of uncertainty. However, logistics robots are not always the most suitable solution, and fixed installations or manual operations may be more efficient in certain cases. Therefore, it is crucial to select the optimal combination of solutions based on a precise understanding of the business environment.